Pad printing is a popular and cost-effective method for printing on many substrates, including plastic, metal, and glass. One of the most critical components of a pad printing machine is the ink cup, which holds the ink and transfers it to the printing plate. The carbide ring for pad printing ink cups is a type of pad printing consumable that plays a critical role in the quality of the print.

This paper will discuss the effect of carbide rings for pad printing ink cups on pad printers. We will begin by examining the composition and properties of carbide rings. We will then explore the importance of using high-quality carbide rings for ink cups and their benefits, including increased durability, reduced ink waste, and improved print quality. Finally, we will discuss the factors to consider when selecting carbide rings for ink cups, including size, compatibility, and cost.

Introduction:

Pad printing is a versatile and efficient process involving transferring ink from a recessed image to a substrate via a silicone pad. The process is commonly used for printing irregularly shaped objects, such as bottles, toys, and electronics. A pad printing machine consists of several components, including the printing plate, ink cup, pad, and ink. The ink cup, also known as a doctor blade, is a vital component of the pad printing process as it holds the ink and controls the amount of ink transferred to the printing plate.

One of the critical factors determining the quality of the pad printing process is the quality of the ink cup. The ink cup must hold the ink securely and prevent evaporation or contamination. Additionally, the ink cup must be durable and resistant to wear and tear to ensure consistent print quality.

The carbide ring for pad printing ink cups is a type of pad printing consumable that plays a crucial role in the quality of the print.

Composition and Properties of Carbide Rings for Ink Cups:

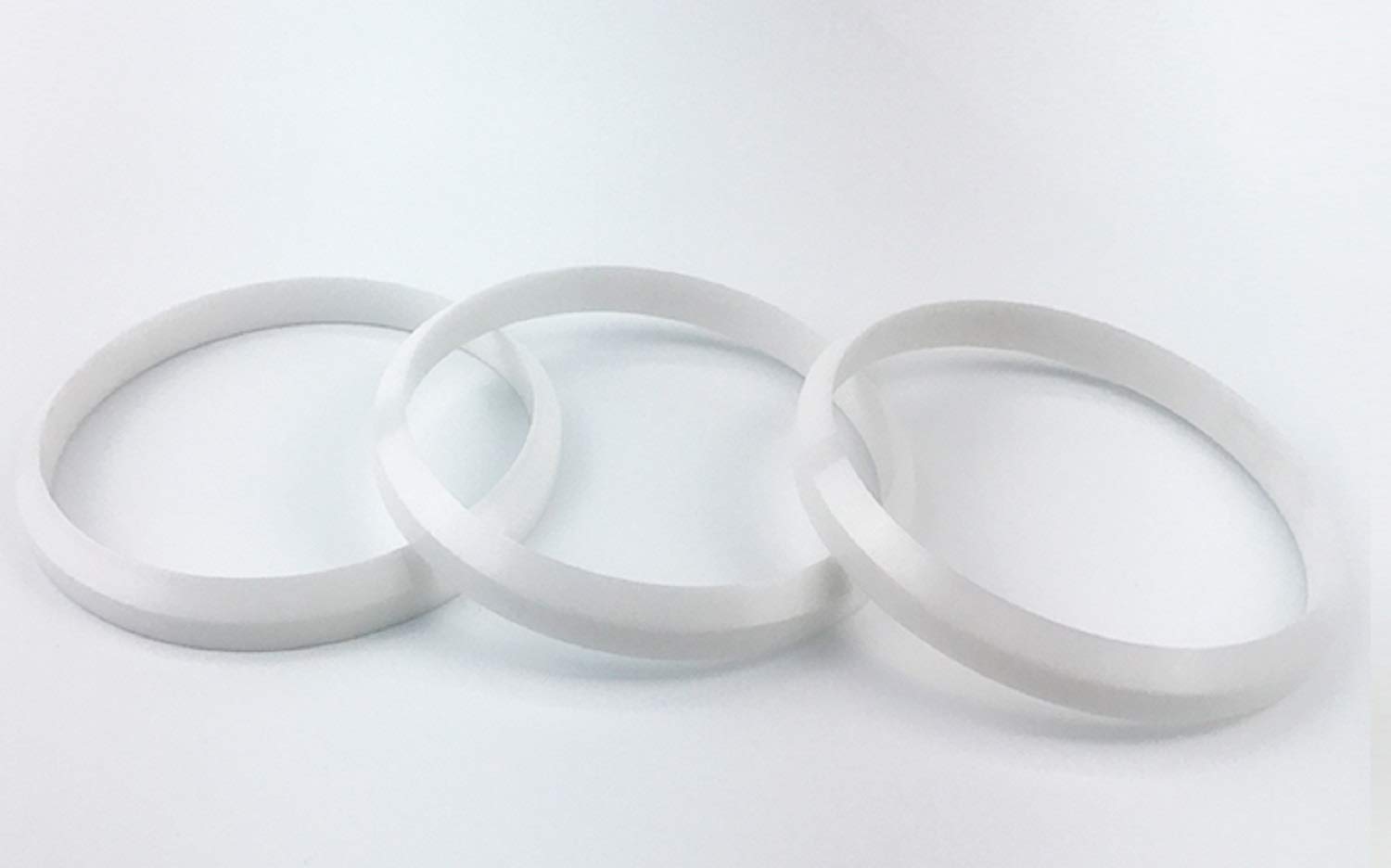

Carbide rings for ink cups are made from tungsten carbide, a rugged and durable material composed of tungsten and carbon. Tungsten carbide is well known for its hardness, wear resistance, and high melting point, making it an ideal material for use in harsh environments.

Carbide rings for ink cups are made using powder metallurgy, which involves mixing tungsten carbide powder with a small amount of cobalt binder. The mixture is then compacted under high pressure and sintered at high temperatures to produce a dense, complex, and wear-resistant material.

Carbide rings for ink cups come in various sizes and shapes, typically used to line the inner rim of the ink cup. The carbide ring is a barrier between the ink and the ink cup, preventing the ink from seeping under the blade and reducing the ink required for each print.

Benefits of Using Carbide Rings for Ink Cups:

Using carbide rings for ink cups offers several benefits over traditional ink cups. Some of these benefits include:

Increased durability: Carbide rings are much more complicated and wear-resistant than traditional steel or ceramic ink cups. They can withstand the wear and tear associated with the pad printing process, resulting in longer ink cup life and reduced downtime.

Reduced ink waste: The carbide ring’s precise fit around the inner rim of the ink cup prevents ink from seeping underneath the blade, reducing ink waste and increasing the number of prints per ink fill.

Improved print quality: The carbide ring’s precise fit and consistent ink transfer result in higher-quality prints with better detail and colour accuracy. Additionally, the carbide ring’s high thermal conductivity helps to maintain a constant ink temperature, ensuring consistent print quality.

Reduced maintenance: Carbide rings require less maintenance than traditional ink cups, as they are less prone to wear and tear and do not require frequent replacement.

Factors to Consider When Selecting Carbide Rings for Ink Cups:

When selecting carbide rings for ink cups, several factors should be considered, including:

Size: The carbide ring must be the correct size for the ink cup to ensure a secure fit and prevent ink leakage.

Compatibility: Carbide rings for ink cups must be compatible with the pad printing machine and ink system used.

Cost: Carbide rings are generally more expensive than traditional ink cups, and the price must be weighed against their benefits.

Quality: The quality of the carbide ring is critical in ensuring a long-lasting and effective ink cup. Purchasing carbide rings from a reputable supplier that uses high-quality materials and production processes is essential.

Conclusion:

The carbide ring for pad printing ink cups is a critical component of the pad printing process that plays a significant role in determining the print quality and machine efficiency. Carbide rings offer several benefits over traditional ink cups, including increased durability, reduced ink waste, and improved print quality.

When selecting carbide rings for ink cups, it is essential to consider factors such as size, compatibility, cost, and quality. It is crucial to purchase carbide rings from a reputable supplier that uses high-quality materials and production processes to ensure the best results.

Using carbide rings for ink cups is a wise investment for pad printing businesses seeking to improve print quality and reduce maintenance costs. With the right carbide ring and proper maintenance, pad printers can expect to achieve consistent and high-quality prints for an extended period, making it a valuable asset for businesses looking to succeed in the competitive world of pad printing.