To understand how to use pad printing equipment properly

Pad printing machine manufacturers introduce the basics that will get you started immediately. Pad printing is a versatile version of screen printing and can generally transfer 2D images to 3D objects. Pad printing equipment transfers images from the printing plate, also known as a cliché. cliché is flooded with ink and wiped clean, so the etched area is only ink. The pad printer uses a mixture of solvent and ink that becomes sticky when exposed to air, increasing the ability of the ink to adhere to the silicone transfer pad. The pad sits on top of the cliché and is pressed against it to pick up the ink.

After the pad is removed from the cliché, it is pressed onto the substrate, the surface to be printed. The pad deposits almost all the ink in the desired location and is lifted off the substrate, ready for the next printing cycle. Pad printing machines can accommodate both large and small batches.

Silicone pads can pick up images from flat surfaces and transfer them to various surfaces, including cylindrical, spherical, concave, and convex surfaces. The goal of all pad printing equipment is to place a controlled thickness of the ink and replicate the original design consistently. However, pad printing is notoriously tricky to master. This is why it is essential to understand and control the variables that affect the pad printing process.

Choosing the Right Pad

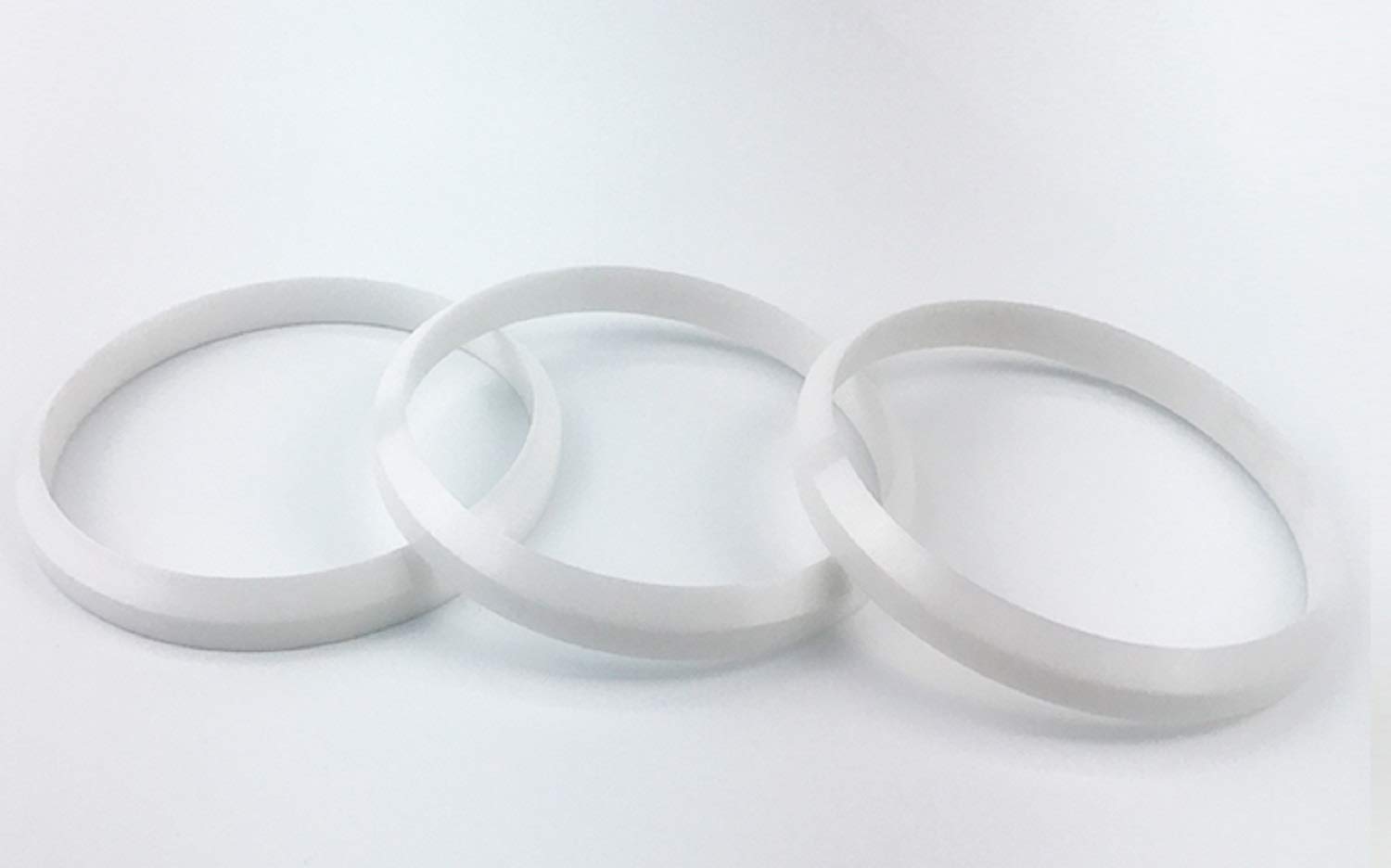

One of the most challenging pad printing problems is determining which pad printing station to use. The critical characteristics of pads that can affect image quality include pad shape, size, hardness, material, and surface finish. The shape is the most crucial variable to consider when selecting a pad. The shape of the pad should allow for a “rolling” action as the ink is picked up from the cliché and deposited on the substrate.

Most pads are round, rectangular, or bar-shaped. Avoid using flat-bottomed pads, as they trap air and impede ink absorption when in contact with the cliché. After unpacking new pad printing tables and other parts of the pad printing machine, it is critical to keep the surfaces of these parts clean, as contaminants can also affect ink adhesion.

Mixing inks

The solvent mixture used in ink is crucial because it affects the rate at which evaporation occurs. 10% thinner is a good starting point. If you feel the ink needs to adhere better to the substrate, slowly add thinner to the ink, but do not exceed 20%. Other factors that affect solvent evaporation include temperature, humidity, and air movement. Changing these conditions will often affect the effectiveness of ink transfer. The solvent should evaporate fast enough to increase the tackiness of the ink surface while always keeping the ink fluid below the surface so that it floats off the etched plate and transfers from the pad.

It is ideal to operate pad printing equipment in an air-conditioned environment with a temperature of 65 to 72 degrees Fahrenheit and a humidity of about 55%. To create the most stable environment possible for pad printing, avoid operating the pad printer near doors, windows, or forced air heaters that open to the outdoors. Using a hair dryer to heat your printing station if you are operating the pad printer in an area below the recommended temperature range.

Buying Quality Pad Printing Equipment

When it comes to padding printing equipment, you get what you pay for, so invest in the best pad printing machine you can afford. It’s also ideal to invest in training rather than wasting labor and machine time trying to learn pad printing on your own. It is also essential to buy pad printing equipment from a company that offers good customer service, as this means that if you need clarification or have a problem, they will always be there to help you.