Introduction

Sustainability and environmental concerns have taken centre stage in today’s ever-evolving manufacturing landscape. Businesses increasingly recognize the need to adopt eco-friendly practices to reduce their carbon footprint and meet the demands of conscientious consumers. This paradigm shift is also evident in the pad printing industry.

With its versatility and ability to apply intricate designs on various substrates, Pad printing plays a pivotal role in industries ranging from electronics to promotional product manufacturing. However, traditional pad printing methods have raised environmental concerns due to solvent-based inks and energy-intensive processes.

As a potential buyer looking for a pad printer, you might be wondering how to reconcile the benefits of pad printing with sustainability goals. In this article, we will explore the eco-friendly side of pad printing and guide you on implementing sustainable materials and techniques. Whether searching for a reputable Pad printer manufacturer or evaluating Pad printer for sale options, understanding these eco-friendly practices is crucial. Additionally, we’ll touch upon the Pad printer price considerations in the context of sustainable choices.

Understanding Pad Printing

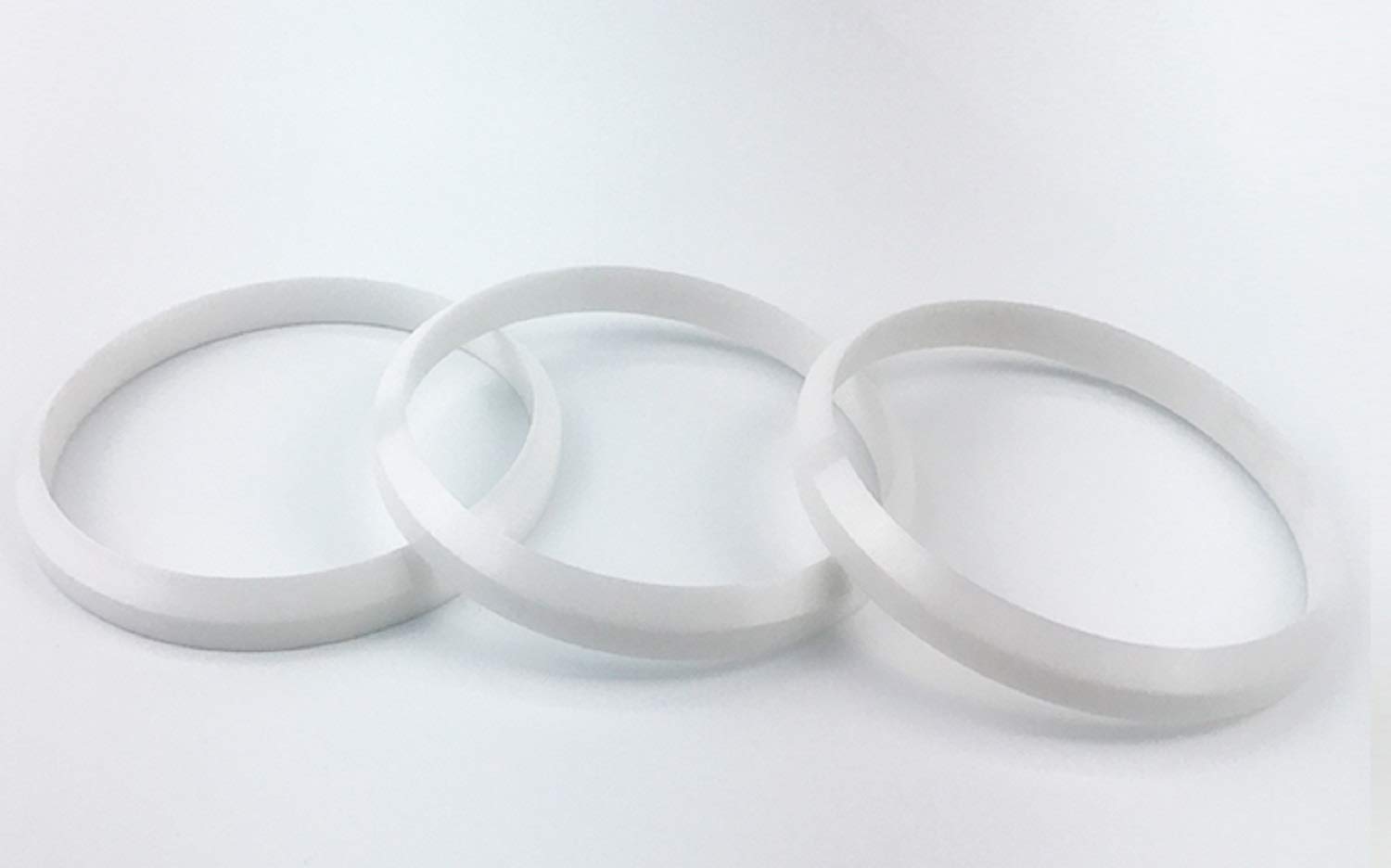

Pad printing, a versatile and widely used printing technique, involves transferring an image from an etched plate to a silicone pad, which then applies the image to the desired substrate. This method is known for its precision, durability, and the ability to print on irregularly shaped objects. Unsurprisingly, pad printing is preferred for industries where intricate designs and high-quality printing are essential.

However, the conventional pad printing process has its drawbacks from an environmental perspective. Traditional pad printing relies on solvent-based inks that contain volatile organic compounds (VOCs). VOCs contribute to air pollution and pose health risks to workers. Additionally, the energy-intensive curing processes used in traditional pad printing consume substantial amounts of electricity.

As you explore options for a pad printer, it’s crucial to weigh the benefits of pad printing against its environmental impact. This article aims to provide insights into minimizing these ecological concerns while enjoying pad printing technology’s advantages. Keep in mind that addressing these concerns often involves collaborating with a responsible Pad printer manufacturer or Pad printer factory that prioritizes eco-friendly practices.

Environmental Impact of Traditional Pad Printing

Traditional pad printing methods have long relied on solvent-based inks, which have several environmental drawbacks:

- Volatile Organic Compounds (VOCs): Solvent-based inks contain VOCs, which are released into the atmosphere during printing and curing. VOCs contribute to air pollution and can adversely affect air quality and human health.

- Waste Generation: The cleanup process in traditional pad printing often generates hazardous waste, including used solvents and contaminated cleaning materials. Proper disposal of this waste can be costly and environmentally challenging.

- Energy Consumption: Curing solvent-based inks often requires high temperatures and extended drying times, leading to increased energy consumption and greenhouse gas emissions.

- Resource Depletion: Traditional printing plates may use unsuitable or recyclable materials, contributing to resource depletion and waste generation.

The pad printing industry is shifting towards more eco-friendly practices to address these environmental issues. By transitioning to sustainable materials and techniques, businesses can significantly reduce their environmental footprint and align with global sustainability goals.

Eco-Friendly Materials and Inks

As environmental consciousness grows, so does the demand for eco-friendly materials and ink in pad printing. Here are some sustainable options to consider:

- Water-Based Inks: Water-based inks are a popular choice for eco-conscious pad printing. They contain fewer harmful chemicals and VOCs compared to solvent-based inks. These inks are better for the environment and safer for workers. Water-based inks are available in various colours and can produce vibrant, long-lasting prints.

- UV-Curable Inks: UV-curable inks have gained traction for their energy efficiency and reduced environmental impact. They require less energy for curing and release fewer VOCs. UV inks also offer fast curing times, increasing production efficiency.

- Soy-Based Inks: Soy-based inks are derived from renewable soybean oil, making them a sustainable choice. These inks are low in VOCs, biodegradable, and easy to clean. They are an excellent option for businesses aiming to reduce their carbon footprint.

- Recycled Substrates: Consider using recycled or sustainably sourced substrates for pad printing. Recycled paper, cardboard, or plastic materials can help minimize the environmental impact of your printed products.

By opting for these eco-friendly materials and inks, you can significantly reduce the adverse environmental effects associated with pad printing. Moreover, such choices can align your business with sustainability goals and appeal to environmentally conscious customers.

Energy-Efficient Techniques

Reducing energy consumption is a critical aspect of making pad printing more eco-friendly. Here are some energy-efficient techniques to consider:

- LED Curing Systems: LED (Light Emitting Diode) curing systems have gained popularity for their energy efficiency and reduced heat output compared to traditional curing methods. LED lamps consume less electricity and have a longer lifespan, reducing maintenance and energy costs.

- Low-Temperature Curing: Some eco-friendly inks are designed to cure at lower temperatures, saving energy during printing. These inks can be a valuable choice for reducing the carbon footprint of your pad printing operation.

- Efficient Machinery: When choosing a pad printer, consider models designed for energy efficiency. Look for features such as automatic shut-off functions and energy-saving modes.

- Process Optimization: Implement efficient printing processes that minimize energy waste. This includes optimizing ink application and drying times to reduce energy consumption.

By adopting these energy-efficient techniques, you can make your pad printing operation more environmentally friendly while reducing long-term operational costs. As you explore different pad printing options, consider whether the manufacturer or factory offers energy-efficient features and technologies.

Sustainable Substrates

Selecting sustainable substrates is another essential aspect of eco-friendly pad printing. Here’s why it matters and how you can make responsible choices:

- Environmental Impact: The choice of substrates, such as paper, plastic, or metal, can significantly impact the ecological footprint of your printed products. Some substrates are derived from finite resources or are non-biodegradable, contributing to environmental degradation.

- Recycled and Biodegradable Options: Look for substrates made from recycled materials or biodegradable ones. Recycled paper and cardboard, for example, are readily available and can be used for a wide range of pad printing applications.

- Responsibly Sourced Materials: Ensure your substrates are sourced from responsible suppliers who follow sustainable practices. This may involve verifying their commitment to sustainable forestry, eco-friendly production processes, and ethical labour practices.

- Life Cycle Assessment: Consider conducting a life cycle assessment (LCA) to evaluate the environmental impact of your chosen substrates throughout their entire life cycle. This can help you make informed decisions about which materials to use.

By choosing sustainable substrates for pad printing, you contribute to reducing your products’ environmental impact and align with eco-friendly printing principles. Many customers appreciate and seek products with sustainable packaging and materials, enhancing your brand’s image.

Regulatory Compliance

Compliance with environmental regulations and certifications is crucial for businesses adopting eco-friendly pad printing practices. Here are some key considerations:

- Environmental Standards: Familiarize yourself with local and international environmental standards and regulations relevant to your industry. Compliance with these standards is legally required and demonstrates your commitment to responsible practices.

- Certifications: Seek out certifications that validate your eco-friendly approach. For instance, ISO 14001 certification focuses on environmental management systems, while Forest Stewardship Council (FSC) certification ensures responsible forestry practices.

- Eco-Labels: Consider using eco-labels on your printed products to inform consumers of your commitment to sustainability. Recognized eco-labels can enhance your product’s marketability.

- Transparency: Communicate your sustainability efforts transparently to customers and stakeholders. Sharing your eco-friendly initiatives and achievements can build trust and goodwill.

By staying compliant with regulations and obtaining relevant certifications, you avoid legal issues and position your business as a responsible and eco-conscious player in the market.

Case Studies

Let’s explore some real-world examples of companies that have effectively implemented eco-friendly pad printing techniques:

Case Study 1: XYZ Electronics

Challenge: XYZ Electronics, a leading manufacturer of electronic devices, faced increasing pressure to reduce its environmental footprint. Traditional pad printing methods using solvent-based inks were no longer sustainable.

Solution: XYZ Electronics transitioned to water-based inks for their pad printing process. They also invested in LED curing systems, reducing energy consumption during production.

Results: The company significantly reduced VOC emissions and energy costs and improved the quality of its prints. Their eco-friendly approach helped them secure new contracts with environmentally conscious clients.

Case Study 2: GreenPrint Promotions

Challenge: GreenPrint Promotions, a promotional products supplier, wanted to align their offerings with their commitment to sustainability. They sought to find eco-friendly pad printing solutions.

Solution: GreenPrint Promotions started using soy-based inks for their pad printing projects. They also switched to substrates made from recycled materials.

Results: Their eco-friendly product line became a hit among customers seeking environmentally responsible promotional items. This shift boosted sales and enhanced the company’s reputation as a green supplier.

These case studies demonstrate how businesses across different industries have successfully integrated eco-friendly pad printing techniques into their operations. Whether you’re a large electronics manufacturer like XYZ Electronics or a smaller promotional products supplier like GreenPrint Promotions, embracing sustainability can yield positive results.

Tips for Implementing Eco-Friendly Pad Printing

Here are some practical tips to help you get started with implementing eco-friendly pad printing techniques in your business:

- Research and Choose the Right Materials: Investigate and select eco-friendly inks and substrates that align with your sustainability goals. Consider water-based inks, UV-curable inks, recycled substrates, and soy-based inks.

- Partner with Eco-Conscious Suppliers: Collaborate with suppliers and manufacturers, prioritizing eco-friendly practices. A responsible Pad printer manufacturer or Pad printer factory can provide you with the necessary equipment and materials.

- Optimize Printing Processes: Fine-tune your printing processes to minimize waste, reduce ink usage, and improve energy efficiency. Regularly maintain and calibrate your equipment for optimal performance.

- Train Your Team: Educate your staff about the importance of eco-friendly practices and proper handling of sustainable materials. Ensure they understand the benefits and methods of using these materials effectively.

- Waste Management: Implement efficient waste management practices, including the proper disposal and recycling of used inks, substrates, and printing plates. Consider implementing a recycling program within your facility.

- Energy-Efficient Equipment: Invest in energy-efficient pad printing equipment, such as machines with LED curing systems. These investments can result in long-term cost savings and reduced energy consumption.

- Promote Your Eco-Friendly Approach: Highlight your commitment to sustainability in your marketing materials and product descriptions. Customers appreciate and support environmentally responsible businesses.

- Monitor and Improve: Continuously monitor your eco-friendly initiatives and seek opportunities for improvement. Regularly assess your environmental impact and adjust your practices accordingly.

Following these tips, you can gradually transition your pad printing operation to be more eco-friendly while meeting your business objectives. Remember that sustainability is an ongoing journey; every step toward reducing your environmental impact is a step in the right direction.

Conclusion

The pad printing industry is evolving to meet these demands in a world increasingly concerned with environmental sustainability. As a potential buyer exploring options for pad printers, understanding the eco-friendly side of pad printing is essential. By implementing sustainable materials and techniques, you can reduce your environmental impact, enhance your business’s reputation, and appeal to conscientious consumers.

In the ever-changing manufacturing landscape, embracing eco-friendly pad printing techniques is a proactive step toward a more sustainable future. By making informed choices, you can reduce your environmental impact while continuing to deliver high-quality prints to your customers.

Thank you for reading, and we hope this article has provided valuable insights into implementing eco-friendly materials and techniques in pad printing. If you have any further questions or need assistance with your pad printing journey, please don’t hesitate to reach out to reputable Pad printer manufacturers and Pad printer factories that share your commitment to sustainability.