In today’s highly competitive market, product decoration and branding are crucial in attracting customers and establishing a solid market presence. One technology that has revolutionized product decoration is the pad printing machine. This article explores the significant role of pad printing machines in product decoration and branding, highlighting their capabilities, advantages, and impact on businesses.

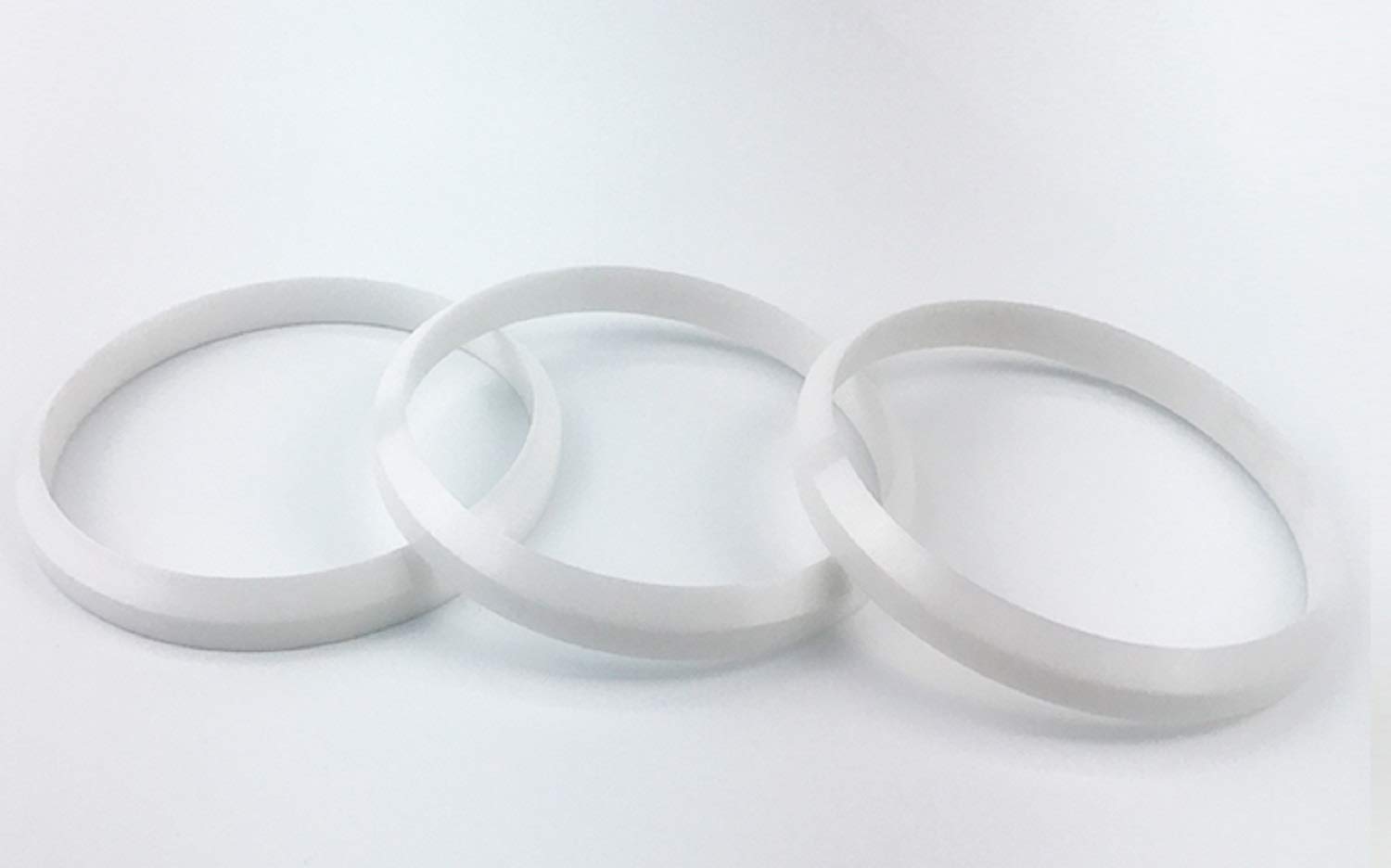

Pad printing is a versatile printing process that allows for the transfer of inked images onto various surfaces. Pad printing machines are specially designed to facilitate this process efficiently and accurately. These machines have several key components, including the ink cup, doctor blade(ceramic/carbide ring ) , silicone pad, and printing plate.

The ink cup holds the ink and ensures controlled and consistent ink transfer. The doctor’s blade (ceramic/carbide ring) removes excess ink from the printing plate, producing sharp and precise prints. The silicone pad picks up the image from the printing plate and transfers it onto the product surface.

Traditionally, product decoration methods such as screen printing or manual painting have limitations regarding precision, detail, and versatility. On the other hand, Pad printing machines have revolutionized product decoration by overcoming these limitations.

Pad printing machines offer exceptional accuracy, enabling intricate designs and fine details to be reproduced with high precision. This capability is particularly beneficial for complex logos, graphics, or text products. The soft silicone pad used in pad printing allows for excellent ink transfer, even on curved or uneven surfaces, expanding the range of products that can be decorated.

Moreover, pad printing machines offer consistent and repeatable results, ensuring that each printed item maintains the same high quality. This consistency is vital for maintaining brand integrity and delivering a professional appearance across different products.

Enhancing Branding Efforts

Branding is fundamental to any business, and pad printing machines contribute significantly to branding efforts. These machines enable enterprises to customize their products with brand logos, slogans, and designs, fostering brand recognition and differentiation.

With pad printing, businesses can easily incorporate branding elements into their products, creating a cohesive and recognizable brand identity. Whether printing a logo on promotional items or branding packaging materials, pad printing machines offer the flexibility to meet various branding needs.

Furthermore, pad printing allows for vibrant and durable inks, ensuring the brand’s colors remain vivid and long-lasting. This durability enhances the longevity of branding efforts and reinforces the perception of high-quality products.

Pad printing machines have transformed how product decoration and branding are approached in today’s competitive market. Their accuracy, versatility, and customization capabilities enable businesses to achieve exceptional results and create a strong brand presence.

By utilizing pad printing machines, businesses can differentiate themselves from competitors, leave a lasting impression on customers, and build brand loyalty. Investing in a high-quality pad printing machine can be a valuable asset for businesses looking to revolutionize their product decoration and branding strategies.

Consider the power of pad printing machines in enhancing your products and capturing the attention of your target audience. Embrace this technology and unlock new possibilities for product decoration and branding success.

The Concept of Pad Printing and Its Advantages

Pad printing is a printing process that allows for the transfer of inked images onto various surfaces. It offers several advantages over traditional printing methods. Firstly, pad printing excels in reproducing intricate designs and fine details with exceptional accuracy. This capability makes it suitable for products that require precise logos, graphics, or text.

Secondly, pad printing is highly versatile and can be applied to various materials, including plastic, metal, glass, and ceramics. This versatility enables businesses to decorate multiple products, from electronic devices and promotional items to household goods and automotive parts.

Lastly, pad printing provides excellent adhesion and durability. The ink adheres well to different surfaces, ensuring long-lasting prints that resist fading, scratching, and other forms of wear. This durability enhances the overall quality and appearance of the printed products.

Components and Functioning of a Pad Printing Machine

Pad printing machines have several key components that facilitate the printing process. These components include the ink cup, doctor blade (ceramic/carbide ring) , silicone pad, and printing plate. The ink cup holds the ink and ensures controlled ink flow. It is designed to contain a small amount of ink, minimizing wastage and allowing for precise ink transfer.

The doctor’s blade (ceramic/carbide ring) removes excess ink from the printing plate. This step ensures that only the desired image is transferred to the silicone pad, producing sharp and precise prints.

The silicone pad is the transfer medium between the printing plate and the product surface. It picks up the inked image from the printing plate and transfers it onto the product with accuracy and consistency.

The printing plate, also known as the cliché, carries the desired image to be printed. It is typically made of metal or polymer and is etched or engraved with the design or pattern to be transferred.

Flexibility and Versatility in Various Industries

Pad printing machines find applications in numerous industries due to their flexibility and versatility. In the automotive industry, these machines print logos, labels, and decorative elements on car parts, such as dashboards, buttons, and knobs.

In the electronics industry, pad printing prints branding elements, serial numbers, and functional symbols on electronic devices and components. The medical industry utilizes pad printing machines to mark medical instruments, equipment, and packaging with identification and instructions.

Additionally, the promotional products industry extensively uses pad printing machines to decorate items like pens, key chains, drinkware, and other personalized merchandise. The versatility of pad printing allows businesses to create unique and eye-catching designs, enhancing their promotional efforts.

Pad printing machines have transformed how product decoration and branding are approached in various industries. Their accuracy, versatility, and customization capabilities enable businesses to achieve exceptional results and create a strong brand presence.

By utilizing pad printing machines, businesses can differentiate themselves from competitors, leave a lasting impression on customers, and build brand loyalty. Investing in a high-quality pad printing machine can be a valuable asset for businesses looking to revolutionize their product decoration and branding strategies.

Consider the power of pad printing machines in enhancing your products and capturing the attention of your target audience. Embrace this technology and unlock new possibilities for product decoration and branding success.

Traditional Methods of Product Decoration and Their Limitations

Before the advent of pad printing machines, traditional methods of product decoration, such as screen printing or manual painting, were commonly used. However, these methods had their limitations. Screen printing, for example, required extensive setup and was unsuitable for small or irregularly shaped objects. Manual painting often resulted in inconsistent quality and was time-consuming for large-scale production.

Overcoming Limitations with Pad Printing Machines

Pad printing machines have overcome the limitations of traditional decoration methods. Firstly, they offer exceptional precision and detailed reproduction, allowing for printing intricate designs and fine lines. This level of accuracy ensures consistent and high-quality prints on various surfaces.

Secondly, pad printing machines provide product shape and size flexibility. The soft silicone pad used in pad printing can conform to uneven or curved surfaces, enabling decoration on complex objects. This versatility opens up new possibilities for product design and branding.

Benefits of Pad Printing in Achieving High-Quality Prints

Pad printing machines offer several benefits that contribute to achieving high-quality prints. The ink transfer process allows for consistent coverage and sharp image reproduction. The controlled ink flow and doctor blade (ceramic/carbide ring) mechanism ensure clean and precise prints, free from smudges or excess ink.

Moreover, pad printing allows for the use of specialized inks, such as UV-curable or solvent-resistant inks, which provide enhanced durability and resistance to fading or wear. This ensures the decorated products maintain their vibrant and attractive appearance over time.

Examples of Products Effectively Decorated using Pad Printing

Pad printing machines have found widespread applications across various industries for product decoration. Some examples of products that can be effectively decorated using pad printing include:

- Electronic devices: Keyboards, remote controls, and computer peripherals.

- Automotive parts: Dashboards, buttons, and interior trims.

- Promotional items: Pens, key chains, drinkware, and personalized merchandise.

- Medical equipment: Instruments, packaging, and medical devices.

Enhancing Branding Efforts

The Importance of Branding in Establishing a Strong Market Presence

Branding plays a critical role in today’s competitive market. It is a strategic process that involves creating a unique identity and perception for a product or company. A strong brand helps businesses differentiate themselves from competitors, build customer loyalty, and establish trust and credibility with their target audience.

The Contribution of Pad Printing Machines to Branding Efforts

Pad printing machines have significantly contributed to branding efforts in product decoration. These machines allow businesses to incorporate brand elements into their products, ensuring consistent and recognizable branding across various items. By leveraging pad printing technology, companies can effectively enhance their brand visibility and create a lasting impression on customers.

Customization Capabilities of Pad Printing for Brand Logos, Slogans, and Designs

Pad printing machines provide remarkable customization capabilities, allowing businesses to imprint their brand logos, slogans, and designs precisely and clearly. The flexibility of pad printing enables the application of branding elements on products of different sizes, shapes, and materials.

With pad printing, businesses can achieve high-quality prints of their brand logos, ensuring they appear vivid and well-defined on various surfaces. This level of customization helps reinforce brand recognition and recall among customers.

Creating Consistent Branding Across Different Products

Consistency in branding is crucial for maintaining a solid brand identity. Pad printing machines facilitate the creation of consistent branding across different products. Businesses can use the same pad printing machine and standardized printing processes to ensure that their brand logos, slogans, and designs are replicated accurately and consistently across their product line.

This consistency in branding helps build a cohesive brand image, enhancing brand recognition and customer recall. Whether printing logos on promotional items or branding packaging, pad printing machines enable businesses to maintain a consistent and professional appearance across their entire product range.

Pad printing machines have revolutionized product decoration and branding by offering customization capabilities and ensuring consistent brand representation across various products. Leveraging the advantages of pad printing, businesses can enhance their branding efforts, differentiate themselves in the market, and establish a solid and memorable brand presence.

By investing in high-quality pad printing machines, businesses can create customized prints of their brand logos, slogans, and designs, leaving a lasting impression on customers and building brand loyalty. Embrace the power of pad printing machines to unlock new possibilities for product decoration and branding success.

Case Studies and Success Stories

Real-life Examples of Businesses Utilizing Pad Printing Machines

Numerous businesses have successfully utilized pad printing machines to enhance their product decoration and branding efforts. Let’s explore some real-life examples:

- Vtech : a manufacturer of electronic devices, implemented pad printing machines to imprint their brand logos and product information on their devices. This allowed them to create a consistent and professional appearance across their product line, reinforcing their brand identity.

- DNZ : a promotional products company, leveraged pad printing machines to customize their merchandise with client logos and slogans. This customization capability helped them attract more clients and offer personalized promotional items aligned with each client’s brand image.

- WT, an automotive parts manufacturer, integrated pad printing machines into their production process. Using these machines, they achieved precise and durable printing of labels, buttons, and decorative elements on their car parts. This improved the overall branding and aesthetic appeal of their products.

Overcoming Challenges with Pad Printing Machines

In each case, these businesses faced specific product decoration and branding challenges. Pad printing machines proved to be instrumental in overcoming these challenges. For example:

- Lefa company faced the challenge of consistently imprinting its brand logos and information on different electronic devices with varying shapes and materials. Pad printing machines provided the flexibility and adaptability to achieve precise prints on diverse surfaces.

- RMMA company needed help meeting the demand for customized promotional items with fast turnaround times. Implementing pad printing machines streamlined the printing process, allowing them to produce personalized products efficiently and meet client deadlines.

- Nandun company needed help finding a printing method that could withstand the demanding conditions and rigorous use of automotive parts. Pad printing machines enabled them to use durable and resistant inks, ensuring long-lasting prints that fought exposure to various environmental factors.

Positive Impact on Branding Efforts and Business Growth

The utilization of pad printing machines positively impacted the branding efforts and overall business growth of these companies. By incorporating their brand elements onto their products with precision and consistency, they achieved the following:

- Enhanced brand recognition and recall: Consistent branding across products created a strong visual identity, making the brand easily recognizable to customers.

- Increased customer loyalty: The prints’ professional appearance and customized nature strengthened customer loyalty, as clients associated the high-quality decoration with the brand’s commitment to excellence.

- Expanded market reach: With personalized promotional items and well-branded products, these businesses were able to attract new customers and enter new markets, expanding their reach and market share.

These case studies demonstrate the positive impact of pad printing machines on product decoration and branding, showcasing how businesses have achieved improved brand visibility, customer loyalty, and overall growth.

Pad printing machines have revolutionized product decoration and branding, allowing businesses to create consistent and customized prints on various surfaces. Through real-life case studies, we have seen how these machines have helped companies to overcome challenges, enhance their branding efforts, and drive business growth.

By harnessing the power of pad printing machines, businesses can achieve precise and durable prints, create a strong brand presence, and differentiate themselves in the competitive market. Embracing this technology opens up new possibilities for product decoration and branding success.

Factors to Consider when Purchasing a Pad Printing Machine

When considering the purchase of a pad printing machine, several factors should be considered to ensure the device meets your specific requirements. These factors include:

- Printing Volume: Assess your printing needs in terms of volume. Determine whether you require a machine for small-scale production or high-volume manufacturing.

- Printing Size and Shape: Consider the size and shape of the products you intend to print on. Ensure the machine can accommodate the dimensions and contours of your products.

- Printing Speed: Evaluate the speed at which the machine can print. This is particularly important if you have tight production deadlines or high output demands.

- Ink Compatibility: Check the machine’s compatibility with various inks and ensure it can handle the specific ink formulations required for your printing applications.

Machine specifications, Printing Capabilities, and Customization Options

To make an informed decision, it’s essential to understand the machine’s specifications and printing capabilities. Consider the following:

- Printing Accuracy: Look for a machine that offers precise registration and consistent ink transfer, ensuring high-quality prints.

- Printing Size Range: Determine the maximum and minimum printing sizes the machine can handle. This will dictate the range of products you can decorate.

- Customization Options: Assess the machine’s ability to customize prints, such as adjustable printing pressure and variable ink deposit control. This flexibility allows for fine-tuning the printing process to achieve desired results.

- Plate and Pad Compatibility: Ensure the machine is compatible with different plate and pad sizes, as well as various types of printing plates (steel, polymer) and pads (silicone, rubber).

Importance of Training and Technical Support

When investing in a pad printing machine, consider the availability of training and technical support from the manufacturer. Adequate training ensures operators can effectively use the device, optimize its performance, and troubleshoot common issues. Technical support assists when encountering challenges or requiring maintenance or repairs.

Choosing a machine from a reputable manufacturer that offers comprehensive training and responsive technical support will contribute to maximizing the efficiency and longevity of the device.

A suitable pad printing machine is crucial for successful product decoration and branding. Businesses can make informed decisions when purchasing a device that aligns with their needs by considering printing volume, size, speed, ink compatibility, and customization options.

Additionally, emphasizing the importance of training and technical support ensures operators can maximize the efficiency and effectiveness of the machine in achieving high-quality prints. With a well-chosen pad printing machine and the necessary help, businesses can harness the power of this technology to revolutionize their product decoration and branding efforts.

Conclusion

Pad printing machines have played a transformative role in product decoration and branding. They have allowed businesses to create customized prints that enhance their brand identity and make a lasting impression on customers. By incorporating their brand elements onto products with precision and consistency, businesses can establish a strong market presence and differentiate themselves from competitors.

The versatility and flexibility of pad printing machines allow for the application of prints on a wide range of products, regardless of their shape, size, or material. This capability has revolutionized how businesses decorate their products, enabling them to achieve high-quality and precise prints that elevate their branding efforts.

If you are a business owner looking to enhance your product decoration and branding, we strongly encourage you to consider incorporating pad printing machines into your operations. These machines offer numerous advantages, including customization capabilities, consistent branding, and the ability to meet various printing needs.

Investing in a high-quality pad printing machine that aligns with your specific requirements can unlock new possibilities for product decoration, establish a strong brand presence, and drive business growth.

Embrace the power of pad printing machines and experience the revolution they can bring to your product decoration and branding endeavors.