Introduction

Pad printing is a crucial technique for transferring ink onto surfaces used in various industries, from electronics to promotional products. A key component in this process is the pad printing ink cup, specifically the ring that maintains ink quality and precision. This article will delve into the differences between carbide rings and ceramic rings for pad printing ink cups to assist users in making an informed purchasing decision.

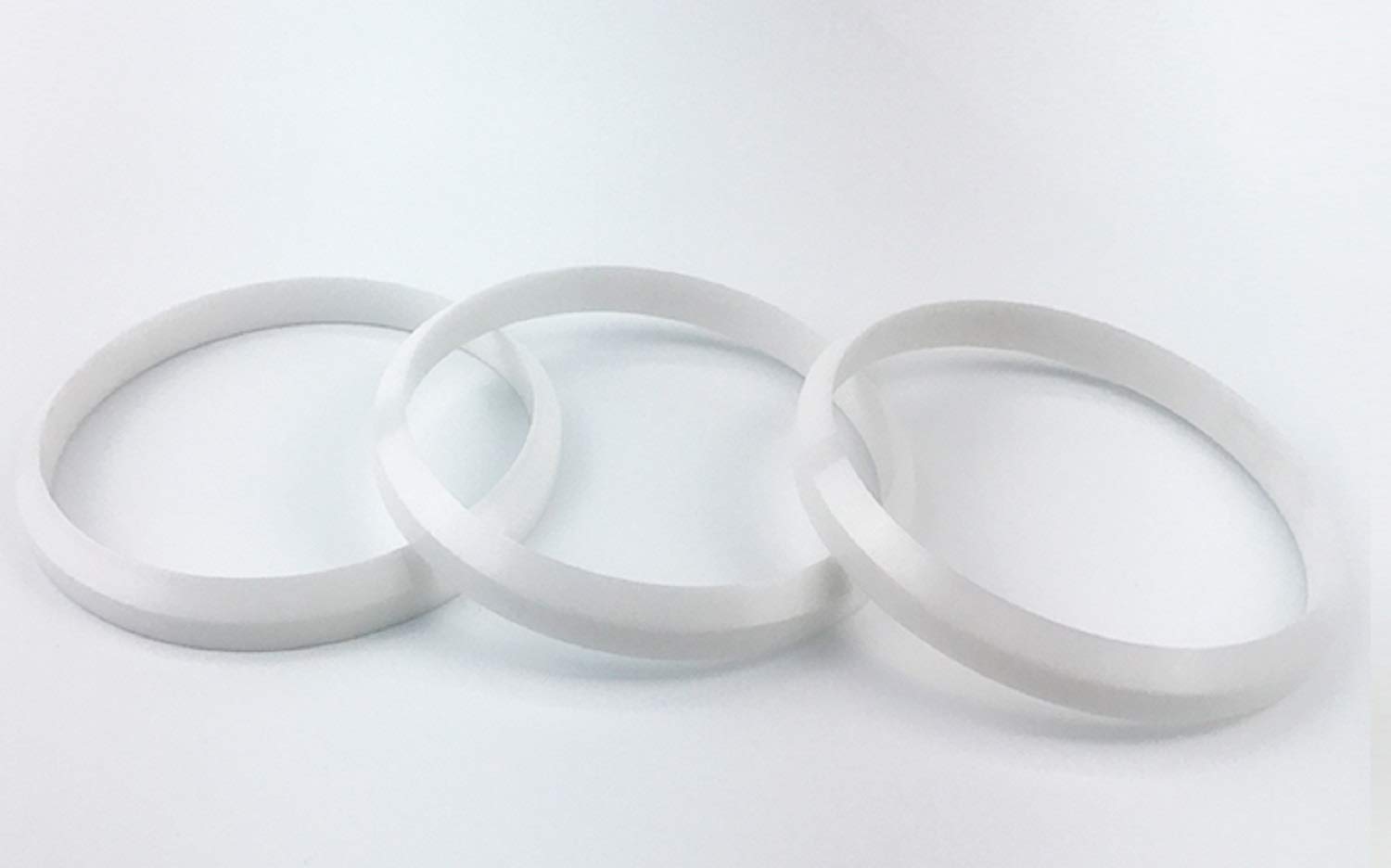

Overview of Pad Printing Ink Cups

Pad printing ink cups play a vital role in ensuring that the ink is contained correctly and transferred to the printing pad. The ring within the ink cup is essential as it scrapes excess ink from the pad, maintaining clean and precise prints. Choosing between a carbide ring and a ceramic ring can significantly impact the performance and cost-efficiency of the pad printing process.

Carbide Rings

Material Properties

Carbide rings are known for their exceptional hardness and durability. Composed mainly of tungsten carbide, these rings are designed to withstand high levels of wear and tear, making them a popular choice for high-volume printing operations.

Advantages

● Durability: The hardness of carbide rings ensures a long lifespan, even under continuous use. This makes them ideal for industries that require consistent, high-quality prints.

● Precision: Carbide rings offer superior print quality with minimal maintenance due to their ability to maintain a sharp edge over time.

● Cost-effectiveness: Although the initial investment is higher, the reduced need for frequent replacements can result in lower long-term costs.

Disadvantages

● Initial Cost: The upfront cost of carbide rings is higher compared to ceramic rings, which might be a consideration for budget-conscious operations.

● Weight: Carbide rings are heavier, which can influence the handling and setup of the printing equipment.

Ceramic Rings

Material Properties

Ceramic rings are made from high-quality ceramic materials, known for their lightweight and chemical resistance. However, they tend to be more brittle compared to carbide rings.

Advantages

● Cost: Ceramic rings generally have a lower initial cost, making them an attractive option for businesses with limited budgets.

● Weight: The lighter weight of ceramic rings can benefit specific printing setups, requiring less force and easier handling.

● Chemical Resistance: Ceramic rings exhibit excellent resistance to certain types of inks and solvents, which can be advantageous in specific printing environments.

Disadvantages

● Fragility: Ceramic rings are more prone to chipping and cracking, which can lead to frequent replacements and potential downtime.

● Wear and Tear: Ceramic rings’ lifespans are typically shorter, resulting in more frequent maintenance and higher long-term costs.

● Inconsistent Print Quality: Ceramic rings’ tendency to wear down faster over time may lead to inconsistent print quality.

Comparison Table

| Feature | Carbide Ring For Pad Printing Ink Cups | Ceramic Ring For Pad Printing Ink Cups |

| Hardness | High | Moderate |

| Lifespan | Long | Less |

| Initial Cost | More | Lower |

| Maintenance Frequency | Lower | Low |

| Weight | Heavy | Lighter |

| Chemical Resistance | Moderate | High |

Application Suitability

Choosing between a carbide ring and a ceramic ring largely depends on the application’s specific requirements. Industries that demand high precision and long-term durability may find carbide rings more suitable, while smaller operations or those with budget constraints might prefer ceramic rings.

Application Suitability

Ceramic rings may be the preferred choice for industries where chemical resistance is a priority, such as medical device manufacturing or electronics, due to their ability to withstand harsh cleaning solvents and ink formulations. Conversely, industries prioritizing precision and consistency, such as automotive part production or consumer electronics, may opt for carbide rings to ensure high-quality prints over extended periods.

Case Studies

Carbide Ring For Pad Printing

A leading automotive manufacturer implemented carbide rings to meet stringent quality standards in their pad printing process. Using carbide rings, they experienced minimal downtime due to ring replacements and consistently achieved sharp, precise prints on various surfaces, including metal and plastic components. Despite the initial investment, the long-term cost savings and improved print quality justified the switch to carbide rings.

Ceramic Ring For Pad Printing

In contrast, due to budget constraints, a small-scale promotional products company opted for ceramic rings in their pad printing setup. While they initially benefited from the lower cost of ceramic rings.

Maintenance and Care Tips

Regardless of the type of ring chosen, proper maintenance is essential to maximize its lifespan and performance. Regular cleaning and inspection of the ring and ink cup can prevent buildup and ensure optimal printing results. For carbide rings, occasional sharpening may be necessary to maintain their sharp edge, while ceramic rings may require more frequent replacements to address wear and chipping.

Conclusion

In conclusion, the choice between carbide rings and ceramic rings for pad printing ink cups involves carefully considering durability, cost, and application requirements. While carbide rings offer superior hardness and long-term performance, they come with a higher upfront cost. On the other hand, ceramic rings provide a more affordable option. By evaluating their specific needs and weighing the advantages and disadvantages of each option, users can make an informed decision that optimizes print quality and cost-efficiency in their pad printing operations.