Overview

For companies wishing to print premium graphics on various substrates, selecting the appropriate pad printing machine is essential. Pad printing machines are available in several configurations; the most common are the 2-color pad printing machine and 4-color pad printing machine. This article aims to assist prospective customers in identifying which of these two machine types best meets their demands by explaining the distinctions between them.

Comprehending Pad Printing Devices

A flexible printing method for projecting 2D graphics onto 3D objects is pad printing. It is frequently employed in many different industries, including toys, medical gadgets, electronics, and promotional goods. A silicone pad is used to transfer ink from an etched plate to the substrate. A pad printing machine’s pad, substrate holder, cliché (plate), and ink cup are essential.

2-Color Pad Printing Machine

Synopsis and Capabilities

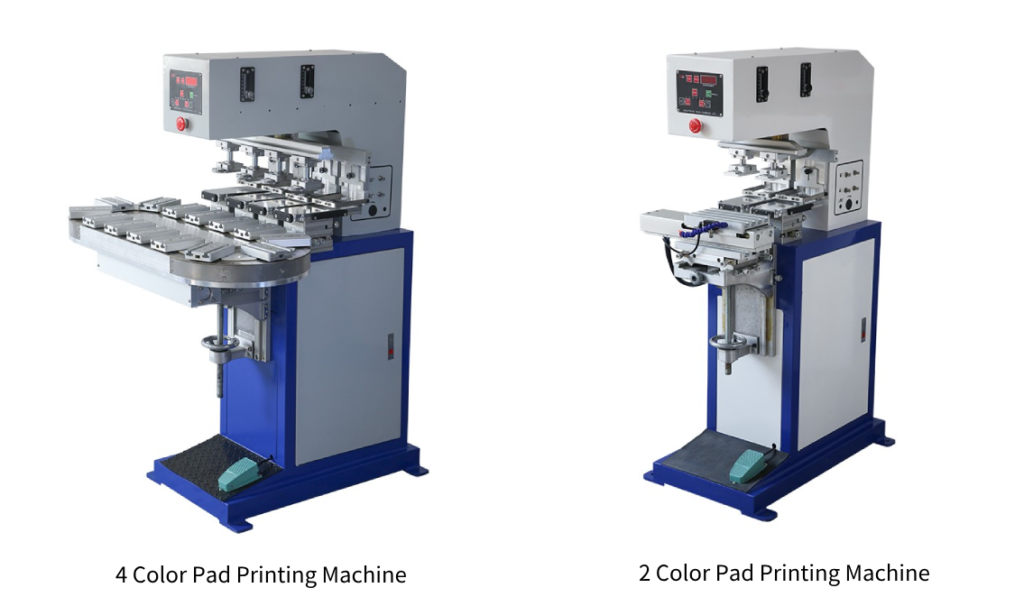

A two-color pad printing machine prints two colors in one cycle. It is perfect for goods with straightforward, two-color graphics. The machine applies each colour using two different ink containers and pads.

Typical Applications and Use Cases

Often, 2-color pad printing machines are used to print labels, logos, and simple graphics on items such as pens, keychains, and tiny electrical components.

Benefits

Expense-effectiveness: 2-color printers are typically less expensive than 4-color printers, so they are a wise option for companies with less complex printing requirements.

Simplicity & Ease of Use: These machines require less technical expertise and are more straightforward to maintain and run.

Conserving Space: Two-color machines use less production floor space because of their smaller size.

Restrictions

Few Colour Selections: The intricacy and vividness of designs are constrained by the availability of just two colours.

Manual Remedials: Compared to 4-color machines, colour alignment and consistency adjustments might need more manual labour.

4-Color Pad Printing Machine

A 4-color pad printing machine can print up to four colours in a single cycle, making more intricate and colourful designs possible. It uses four distinct ink cups and pads, one for each colour.

Typical Applications and Use Cases

These machines can print intricate, multicoloured graphics on toys, medical equipment, and promotional goods. They are very helpful when creating complex and visually striking images.

Benefits

intricate and colourful designs:Prints with greater detail and colour are possible when four colours are available.

Effectiveness: Increased productivity in multi-colour printing minimizes the requirement for extra cycles and human tweaks.

Decreased Need for Manual Intervention: Operator intervention is reduced automatically when colour adjustments and alignments are made.

Restrictions

More significant Cost: The initial investment and running costs of 4-color equipment are higher.

Due to their bigger size:these machines necessitate a more expansive production floor.

Enhanced Complexity: Skilled operators are needed for the more complex setup and maintenance.

Key Considerations for Choosing Between 4-Color and 2-Color Machines

The following elements should be taken into account when choosing between a 4-color and a 2-color pad printing machine:

- Character of the Good: Consider the intricacy of the designs and the colour specifications for your merchandise.

- Volume and Rate of Production: Establish the speed and amount of output you need.

- Financial Restraints: Consider your budget for the initial outlay and continuing operational expenses.

- Space Availability: Ensure the machine has enough room in your production area.

- Operator Skill Level: Assess your operators’ level of technical proficiency.

Analyzing Costs

Expenses of the First Investment

A 2-color pad printing machine often has a lower beginning cost than a 4-color machine. However, the features of the device and the manufacturer of the pad printer determine the exact cost.

Costs of Operation and Maintenance

Due to their greater complexity and quantity of parts, four-color machines usually have higher operating costs, including ink and pad consumption. They also typically require more frequent service and specialized personnel, which raises maintenance costs.

ROI and Long-Term Financial Gains

Even though a 4-color machine has more excellent startup and running expenses, its capacity to create intricate and colourful graphics can draw in more clients, which could eventually result in a higher return on investment (ROI).

Practical Illustrations and Case Studies

An Illustration of a Company That Gained from a 2-Color Printer

A small business specializing in personalized pens and key chains decided to purchase two-color pad printing equipment. Their main requirement was to produce two-color versions of simple logos. The 2-color machine’s affordability and user-friendliness enabled them to generate superior items without requiring a substantial upfront expenditure. Their ability to efficiently complete large orders resulted in higher customer satisfaction and repeat business; thus, this investment paid off immediately.

An Illustration of a Company That Gained from a 4-Color Printer

A manufacturer of medical devices needed their products to have intricate, multicoloured branding. To obtain the accuracy and vibrancy required for their drawings, they decided to use a 4-color pad printing process. The machine’s efficiency and decreased need for manual intervention led to shorter production times and better-quality output, even with the higher cost. Their capacity to print intricate graphics offered them a competitive advantage in the market, which boosted sales and established their brand.

Best Practices and Takeaways

These illustrations demonstrate how the decision between 2-color and 4-color pad printing equipment is based on certain business requirements. Businesses ought to Evaluate Product Needs and recognize the intricacy and colour requirements of their products.

Think About Production Scale: Align the machine’s output volume with its capabilities.

Analyse the Financial Effects: Compare the short-term gains with the long-term investment.

Future Directions for Pad Printing Technology Developments

Technology is constantly changing the pad printing business, with the goal of increasing productivity and print quality. Thanks to innovations such as automated colour modifications, digital interfaces, and sophisticated ink formulas, pad printing machines are becoming more user-friendly and able to handle intricate designs.

Future Prospects for Multi-Color Printing

Future advances are possible for more eco-friendly ink alternatives, quicker production cycles, and improved colour registration precision. These developments will increase the versatility and efficiency of pad printing machines by further muddying the distinctions between them.

Changes in the Industry and Customer Needs

Advanced pad printing technologies will become increasingly necessary as consumer demands for high-quality, personalized products rise. Companies will look for machinery that can handle a variety of materials and designs, has excellent precision, and is flexible.

In summary

Making the critical choice between a 4-colour and a 2-colour pad printing machine depends on several variables, such as the complexity of the product, the volume of production, the available funds, and the available space. 4-color machines offer more versatility and efficiency for more complicated designs, while 2-color machines are more affordable and accessible.

Prospective customers should carefully consider their unique demands and speak with a reliable pad printer manufacturer or supplier to make an informed choice. By doing this, companies can ensure their purchase machines will fulfil their needs and foster expansion.