A pad printing cliche plate, also known as a printing plate or cliché, is a fundamental component in the pad printing process that holds the etched image or artwork. This plate is flooded with ink, and a doctor blade or ring scrapes the surface, leaving ink only within the etched depression. A silicone pad then presses onto the plate to pick up the ink from the etching and transfers it to the substrate (the object being printed). The quality, material, and etching of the cliche plate directly dictate the final print’s sharpness, consistency, and durability, making it a critical element for achieving high-quality results.

Table of Contents

- What is a Pad Printing Cliche Plate?

- A Deep Dive into Cliche Plate Materials

- The Art and Science of Etching: Creating the Image

- How to Choose the Perfect Cliche Plate: A Practical Checklist

- Cliche Plate Best Practices: Care and Maintenance

- Conclusion: The Critical Role of the Cliche Plate

What is a Pad Printing Cliche Plate?

Imagine the cliche plate as the master template or stamp in the pad printing universe. It is the origin point of your printed image. This flat plate, typically made of steel or a light-sensitive polymer, contains a precise, shallow depression—or “etch”—in the shape of the desired artwork. The depth of this etch is meticulously controlled, as it determines the volume of ink that will be transferred, which in turn affects the opacity and thickness of the final print. Without a high-quality, accurately etched plate, even the most advanced pad printing machine cannot produce a clear and consistent image.

The process is elegantly simple yet mechanically precise. First, the entire plate surface is covered in ink. Next, a doctor blade (in an open inkwell system) or a ceramic ring (in a sealed cup system) slides across the plate, wiping the surface clean. This “doctoring” action leaves a precisely metered amount of ink only in the recessed, etched artwork. At this point, a flexible silicone pad descends, presses onto the etched area, and lifts the ink image. The pad then moves over to the product and transfers the ink layer onto its surface. This entire cycle relies on the cliche’s ability to hold ink perfectly and release it cleanly, cycle after cycle.

A Deep Dive into Cliche Plate Materials

The material of your cliche plate is one of the most significant factors influencing your project’s cost, efficiency, and print quality. The choice between different materials isn’t about which is universally “better,” but which is best suited for your specific application, considering factors like run volume, artwork complexity, and budget. The two primary materials dominate the industry: photopolymer and steel.

Photopolymer Plates: The Versatile Standard

Photopolymer plates are plastic-based plates with a light-sensitive coating. They are highly popular due to their affordability and the ability to be processed quickly and easily in-house, offering great flexibility for short to medium production runs. They are exposed to UV light through a film positive of the artwork, and the unexposed areas are then “washed out” using a specific solvent, leaving the etched image behind. This makes them ideal for jobs requiring rapid turnaround times or frequent artwork changes.

There are two main categories of photopolymer plates, distinguished by their washout solvent:

- Water-Wash Plates: As the name suggests, these plates are developed using plain water. This makes them more environmentally friendly and safer to handle, eliminating the need for harsh chemicals. They are excellent for standard line art and are known for creating a slightly rounded bottom in the etch, which can be beneficial for ink pickup and release.

- Alcohol-Wash Plates: These plates require a special alcohol-based solution for washout. They are generally capable of holding finer details, sharper edges, and smaller halftone dots than their water-wash counterparts. This makes them the preferred photopolymer choice for more intricate or high-resolution graphics.

Despite their versatility, photopolymer plates have a limited lifespan, typically lasting for 10,000 to 40,000 impressions, depending on the plate type, ink, and machine setup (open inkwell vs. sealed cup). They are more susceptible to wear from abrasive inks or aggressive doctoring.

Steel Plates: The Durable Powerhouse

When longevity and unwavering consistency are paramount, steel plates are the undisputed champions. Made from high-quality, hardened steel, these plates are engineered for high-volume production, capable of withstanding hundreds of thousands to over a million impressions with proper care. Their extreme hardness ensures a crisp, clean doctoring action and makes them highly resistant to scratches and wear, resulting in unparalleled print consistency throughout a long run.

Steel plates come in two main formats:

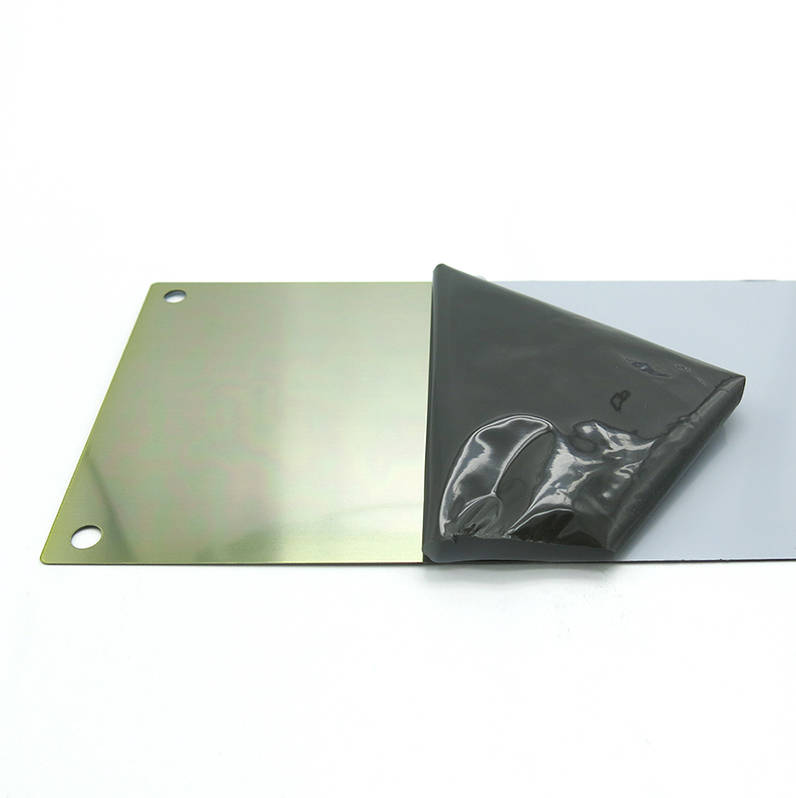

- Thin Steel Plates: These plates are approximately 0.5mm thick and offer a compromise between the durability of steel and the flexibility of photopolymer. They are more durable and provide sharper detail than polymer plates but are less expensive and easier to handle than their thick steel counterparts. They are a popular choice for medium to long runs where high quality is essential.

- Thick Steel Plates: At around 10mm thick, these are the workhorses of the pad printing world. Their thickness provides maximum stability and flatness, making them ideal for the most demanding, high-volume industrial applications. They offer the longest life and the highest possible print quality, especially for extremely fine details and halftones.

The primary drawbacks of steel plates are their higher upfront cost and the more complex etching process, which is often outsourced to specialized suppliers. However, for large-scale production, their low cost-per-print and reliability make them a wise long-term investment.

Material Comparison: Which Cliche Plate is Right for Your Project?

To simplify your decision, here is a direct comparison of the key attributes of photopolymer and steel plates.

| Attribute | Photopolymer Plates | Thin Steel Plates | Thick Steel Plates |

|---|---|---|---|

| Lifespan (Impressions) | 10,000 – 40,000 | 50,000 – 150,000 | 500,000 – 1,000,000+ |

| Upfront Cost | Low | Medium | High |

| Resolution/Detail | Good to Very Good | Excellent | Superior |

| Processing Time | Fast (minutes, in-house) | Moderate (often outsourced) | Slow (almost always outsourced) |

| Best For | Short runs, prototypes, quick turnarounds | Medium-to-long runs, high-quality needs | Very long runs, industrial-scale production |

The Art and Science of Etching: Creating the Image

Etching is the process of creating the recessed artwork on the cliche plate. The precision of the etch—its depth, wall straightness, and bottom texture—is as crucial as the plate material itself. A poor etch will lead to problems like incomplete ink transfer, fuzzy edges, or inconsistent print density. The goal is to create an “inkwell” that is deep enough to hold sufficient ink for opacity but shallow enough to allow for a clean pickup by the pad. The two dominant etching technologies are traditional chemical etching and modern laser etching.

Chemical Etching: The Traditional Method

Chemical etching is the long-established method for creating images on both photopolymer and steel plates. The process involves using a photo-sensitive mask (or emulsion) and a corrosive chemical (an etchant) to selectively remove material from the plate.

The typical steps for chemical etching are:

- Plate Coating: The steel plate is coated with a uniform layer of light-sensitive emulsion.

- Exposure: A film positive of the artwork is placed on the coated plate, and both are exposed to a strong UV light source. The light hardens the emulsion in the non-image areas.

- Developing: The plate is washed with a developer, which removes the unhardened emulsion from the image areas, exposing the bare steel underneath.

- Etching: The plate is sprayed with or submerged in an acidic solution, such as ferric chloride. The acid eats away at the exposed steel, creating the recessed image. Etch depth is controlled by the duration of this step.

- Stripping: Finally, the remaining hardened emulsion mask is chemically stripped from the plate, leaving the finished, etched steel cliche.

While effective and widely used, chemical etching requires careful handling of hazardous materials and precise control over variables like temperature and time to ensure consistency. It can sometimes result in a slightly “dished” or rounded etch profile, which may be undesirable for ultra-fine details.

Laser Etching: The Modern Precision Method

Laser etching, also known as laser engraving, is a direct-to-plate digital process that has revolutionized cliche making. It uses a high-powered laser beam, controlled by computer software, to directly ablate or vaporize material from the plate’s surface. This eliminates the need for films, chemicals, and multi-step processing, offering unparalleled precision and repeatability.

The key advantages of laser etching are:

- Precision and Control: Lasers can create exceptionally fine details, sharp corners, and straight-walled etches. Etch depth can be controlled with micron-level accuracy.

- Consistency: Since the process is digitally controlled, every plate is an exact replica of the first. This is crucial for multi-color jobs or repeat orders.

- Speed and Efficiency: It’s a single-step process that goes directly from a digital file to a finished plate, significantly reducing turnaround time.

- Environmental Benefits: Laser etching eliminates the use and disposal of hazardous chemicals associated with chemical etching.

Different lasers are used for different materials. CO2 lasers are typically used for photopolymer plates, while more powerful YAG or Fiber lasers are necessary to effectively etch the much harder surface of steel plates. The main barrier to in-house laser etching is the high capital investment required for the equipment.

Etching Method Showdown: Laser vs. Chemical

How do these two methods stack up? Use this table to compare them at a glance.

| Feature | Laser Etching | Chemical Etching |

|---|---|---|

| Process | Digital, single-step, direct-to-plate | Analog, multi-step (film, expose, develop, etch) |

| Precision | Extremely high; micron-level control | Good to very good; dependent on operator skill |

| Repeatability | Perfect; 100% digital consistency | Variable; relies on tight process control |

| Consumables | None (other than the plate) | Film, emulsion, developers, etchants, strippers |

| Environmental Impact | Low; no chemical waste | High; involves hazardous chemicals and waste disposal |

| Equipment Cost | Very High | Low to Moderate |

How to Choose the Perfect Cliche Plate: A Practical Checklist

Selecting the right cliche plate involves balancing performance, cost, and logistics. Ask yourself these key questions to guide your decision:

- What is my production run volume? For short runs or prototypes (<10,000 impressions), photopolymer plates are the logical choice. For medium to long runs, thin steel offers a great balance. For massive industrial runs (>100,000 impressions), thick steel is the only way to ensure longevity.

- How complex is my artwork? For standard text and logos, most plate types will suffice. For ultra-fine lines, negative text, or complex halftone screens, a laser-etched steel plate will provide the best definition and clarity.

- What is my budget and turnaround time? If speed and low upfront cost are critical, an in-house photopolymer plate system is unbeatable. If you can accommodate a higher initial cost and longer lead time for superior long-term value, outsourced steel plates are the better investment.

- Which pad printing system am I using? Sealed cup systems are gentler on plates, extending their lifespan compared to open inkwell systems that use a steel doctor blade. This might allow you to use a photopolymer plate for a slightly longer run than you otherwise would.

- Do I have the resources for in-house plate making? Making photopolymer plates requires a UV exposure unit, washout station, and a ventilated area. Chemical etching of steel requires extensive safety precautions and chemical handling expertise. Laser etching requires a significant capital investment. If these are not feasible, partnering with a reliable plate-making supplier is your best option.

Cliche Plate Best Practices: Care and Maintenance

A cliche plate is a precision tool. Treating it as such will maximize its life and ensure consistent print quality. Follow these best practices for care and handling:

- Proper Cleaning: Clean plates immediately after a print run using the manufacturer-recommended solvent. Do not let ink dry in the etching, as it can be extremely difficult to remove and can damage the plate surface. Use soft, lint-free cloths to avoid scratching.

- Careful Handling: Avoid touching the etched area with your fingers, as oils can affect ink adhesion. Never use sharp metal tools to scrape dried ink from the plate, especially on photopolymer plates. Use a soft plastic scraper or a solvent-soaked cloth instead.

- Smart Storage: After cleaning, apply a light coating of protective oil or spray to steel plates to prevent rust. Store all plates flat, in a clean, dry, and dust-free environment. Use protective sleeves or interleaving paper to prevent plates from scratching each other.

- Inspect Before Use: Before mounting a plate for a new run, inspect it under magnification for any scratches, contamination, or signs of wear in the etch. A quick inspection can prevent a bad print run before it even starts.

Conclusion: The Critical Role of the Cliche Plate

The cliche plate is far more than just a piece of metal or plastic; it is the very foundation of a successful pad printing operation. The choice of material—flexible photopolymer or durable steel—and the method of image creation—traditional chemical etching or precise laser etching—each have profound implications for your workflow, budget, and the quality of your final product. By understanding the unique strengths and weaknesses of each option, you can make an informed decision that aligns perfectly with your production needs.

Ultimately, investing in the right cliche plate and implementing proper care practices is an investment in quality, efficiency, and consistency. A well-chosen, meticulously maintained plate will reward you with crisp, vibrant prints, run after run, solidifying the reputation of your products and your printing process.

pad printing cliche plates, cliche plate materials, pad printing etching, what are pad printing cliche plates, photopolymer vs steel cliche plates, laser vs chemical etching for pad printing, how to choose a pad printing plate, thin steel vs thick steel plates, pad printing plate depth, cliche plate, printing plate materials