Used On : Pad printer ink cup

Material: Ceramic ( Zirconia(ZrO2) )

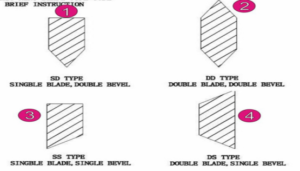

Edge: Single / Double edges

Bevel: Single / Double bevels

Services : Customized service is acceptable

Product detail:

The purpose of using ceramic ring on pad printing ink cups:

Sealed ink cups is able to be filled with different inks , it will be mounted on pad printer, with the help of different types of rings, the blade can scrape the ink well on plate and enable pad takes suitable ink to print the logo on product.

We supply ceramic rings / carbide( Tungsten steel ) rings / customized rings

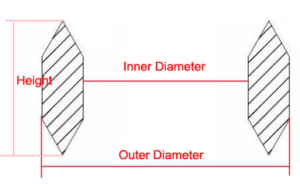

Ring Blade Sizes: ( listed as below but sizes are not limited )

| 60/65/5.2[mm] | 60/70/6.5[mm] | 60/70/12[mm] | 65/70/8[mm] | 80/90/12[mm] |

| 82/90/1.2[mm] | 90/95/5.2[mm] | 90/96/6[mm] | 90/96/8[mm] | 90/100/12[mm] |

| 110/120/12[mm] | 120/130/12[mm] | 135/140/6[mm] | 140/150/12[mm] | 180/192/12[mm] |

Ring Blade Types:

Pad-printing ceramic rings, also known as pad-printing rings or printing doctor blade, are circular-shaped elements made from ceramic materials. They are specifically designed to scrape the ink and transfer it from the etched plate (cliché) to the printing surface (substrate). These rings act as a medium for sharing ink, enabling the creation of high-quality prints with fine details and vibrant colours.

Pad printing ceramic rings play a crucial role in pad printing, offering numerous benefits and ensuring high-quality results. This comprehensive guide will explore pad printing ceramic rings’ purpose, importance, and critical features.

Using pad-printing ceramic rings brings several advantages to the pad-printing process. Let’s take a closer look at some of these benefits:

The advantages of pad printing ceramic rings make them indispensable tools in the pad printing process. Their enhanced wear resistance ensures longer-lasting performance, while their superior ink transfer capabilities result in high-quality prints. The dimensional stability of ceramic rings guarantees consistent and precise printing results, and their easy cleaning and maintenance contribute to increased efficiency. These advantages collectively make pad printing ceramic rings reliable for achieving optimal results in various printing applications.

To meet various printing requirements, pad printing ceramic rings come in different sizes, shapes, and hardness levels. Here are some key features and specifications to consider:

Pad-printing ceramic rings are primarily composed of advanced ceramic materials. These ceramics, such as alumina (Al₂O₃) or zirconia (ZrO₂), are chosen for their exceptional properties. The manufacturing process involves carefully shaping, sintering and firing the ceramic material to achieve the desired ring shape and then grinding to achieve different blade type.

Pad printing ceramic rings have wide-ranging applications across industries thanks to their versatility and ability to deliver precise, high-quality prints. Let’s explore the common industries where these rings are used and delve into specific printing scenarios where they excel.

Pad printing ceramic rings are extensively employed in various industries, including:

Use Pad printing ceramic rings offer exceptional capabilities in various printing scenarios, enabling printing on challenging surfaces and achieving intricate and fine-detail prints. Here are a few examples:

Pad printing ceramic rings have many applications across industries, from automotive and electronics to promotional products and medical devices. They excel in printing on curved and uneven surfaces and textured materials while maintaining their ability to achieve intricate and fine-detail prints. The versatility and precision of pad printing ceramic rings make them indispensable tools for achieving high-quality images in various printing scenarios.

Choosing the right pad printing ceramic ring ensures optimal performance and high-quality prints. In this section, we will discuss the key factors to consider when selecting a ceramic ring, emphasize the importance of compatibility with the printing machine, and provide tips for determining the appropriate ring size and type based on specific printing requirements.

When choosing a pad-printing ceramic ring, several factors should be taken into account:

Ensuring compatibility between the pad printing ceramic ring and the machine is crucial for achieving optimal performance. The ring should be selected based on the specifications and requirements of the printing machine. Factors such as the mounting mechanism, ring holder design, and ink cup size should be considered to ensure proper alignment and smooth operation. It is recommended to consult the manufacturer’s guidelines or seek expert advice to ensure compatibility between the ceramic ring and the printing machine.

To determine the appropriate size and type of pad-printing ceramic ring, consider the following tips:

Taking these factors into account will help select the right pad printing ceramic ring that meets the printing process requirements, substrate, and desired print quality.

Choosing the right pad printing ceramic ring is vital for achieving optimal printing results. Considering ring diameter, hardness, and shape will help ensure the appropriate selection. Additionally, ensuring compatibility with the printing machine is crucial for smooth operation and alignment. By carefully assessing the printing requirements and seeking expert advice, it is possible to determine the most suitable ring size and type for specific printing needs.

Proper maintenance and care of pad printing ceramic rings are essential for maximizing their lifespan and ensuring optimal printing performance. In this section, we will provide guidelines for cleaning and maintenance, emphasize the importance of regular inspections and replacement of worn-out rings, and offer troubleshooting tips for common issues encountered during pad printing with ceramic coils.

Follow these guidelines to clean and maintain pad printing ceramic rings effectively:

Regular inspections of pad printing ceramic rings are crucial to identify signs of wear or damage. Here’s why regular reviews and timely replacement are essential:

Here are some troubleshooting tips for common issues encountered during pad printing with ceramic rings:

Proper cleaning, maintenance, regular inspections, and timely replacement of pad printing ceramic rings are essential for achieving consistent and high-quality prints. By following the cleaning and maintenance guidelines, inspecting for wear, and promptly replacing worn-out rings, you can ensure optimal performance and longevity of the ceramic rings. Additionally, troubleshooting common issues encountered during pad printing will help overcome printing challenges and maintain optimal printing results.

Pad printing ceramic rings are essential components in the pad printing process, offering a range of advantages that contribute to efficient and high-quality printing. We have highlighted their enhanced wear resistance, superior ink transfer capabilities, dimensional stability, and easy cleaning and maintenance. These features make pad printing ceramic rings reliable tools for achieving consistent and precise prints on various substrates.

The enhanced wear resistance of ceramic rings ensures longer-lasting performance, reducing downtime for ring replacements and increasing productivity. Their superior ink transfer capabilities produce high-quality prints with vibrant colours and fine details. The dimensional stability of ceramic rings guarantees consistent and precise printing results, even on complex or irregular surfaces. Moreover, their easy cleaning and maintenance contribute to increased efficiency in the printing process.

When selecting the right pad printing ceramic ring, it is essential to consider factors such as ring diameter, hardness, and shape. Ensuring compatibility with the printing machine is crucial for optimal performance. By following the guidelines for cleaning and maintenance, regularly inspecting and replacing worn-out rings, and troubleshooting common issues, users can maximize the lifespan and performance of pad printing ceramic rings.

Pad printing ceramic rings find applications in various industries, including automotive, electronics, promotional products, and more. Their versatility makes them suitable for multiple printing requirements, from small and intricate designs to larger surface prints.

As you explore the options available, we encourage you to choose high-quality ceramic rings that meet your specific pad printing needs. Consult with suppliers or experts to select the right size, hardness, and shape for your printing applications. By investing in high-quality pad printing ceramic rings, you can achieve consistent, high-quality prints and enhance the overall efficiency of your printing process.

In conclusion, pad printing ceramic rings is integral to the success of the pad printing process. Their durability, superior ink transfer capabilities, dimensional stability, and ease of maintenance make them indispensable tools for achieving optimal printing results. Embrace the benefits of pad printing ceramic rings and elevate your pad printing experience.

Q1: What dimensions are available for ceramic rings used in pad printing?

A1: Ceramic rings for pad printing are available in various dimensions, including different diameters and doctor blade. The specific measurements offered may vary depending on the manufacturer and the model of the ceramic ring. Checking with the supplier or manufacturer for the available options is recommended.

Q2: Are there different shapes available for ceramic rings used in pad printing?

A2: Yes, ceramic rings for pad printing are available in various shapes to accommodate different printing requirements. Common conditions include round, oval, square, and rectangular. The choice of form depends on factors such as the shape of the artwork to be printed and the size and shape of the substrate. Consider your printing needs and consult suppliers to find the most suitable form for your application.

Q3: Can I use any ceramic ring for my pad printing machine?

A3: Ensuring compatibility between the ceramic ring and your pad printing machine is essential. Different devices may have specific requirements regarding ring diameter, mounting mechanism, or other features. Refer to the specifications provided by the manufacturer of your pad printing machine to determine the compatible ceramic ring options. Consulting with suppliers or experts in the field can also help you identify the right ceramic ring for your specific device.

Q4: Are there different materials used to manufacture pad printing rings?

A4: Yes, normally , there are two types of material to make pad printer rings: zirconia and Tungsten steel. These materials offer other properties, such as durability, heat resistance, and chemical resistance. The choice of material depends on the specific printing requirements and the compatibility with the ink and substrates used in your application.

Q5: Can I order customized ceramic rings with specific dimensions or designs?

A5: Some manufacturers may offer the option to customize ceramic rings according to specific dimensions or designs. This allows you to tailor the rings to your unique printing needs. However, customization options may vary among suppliers, so it is recommended to inquire with the manufacturer or supplier regarding their customization capabilities and any additional costs or lead times associated with custom orders.

Q6: Are there any recommended accessories or additional tools for using ceramic rings in pad printing?

A6: The requirements for using ceramic rings in pad printing may vary depending on the specific machine and setup. In addition to the ceramic rings, you may need accessories such as ink cups, and seal rubber rings, It is advisable to consult the manufacturer’s guidelines or seek expert advice to determine the specific accessories or tools required for your pad printing setup.

Q7: How can I ensure the quality and reliability of the ceramic rings I purchase?

A7: To ensure the quality and reliability of the ceramic rings, it is recommended to purchase from reputable suppliers or manufacturers with a proven track record. Look for certifications or quality standards compliance that demonstrate their commitment to producing high-quality products. Additionally, reading customer reviews and testimonials can provide insights into the experiences of other buyers and their satisfaction with the ceramic rings.

Q8: What is the typical lifespan of a ceramic ring for pad printing?

A8: The lifespan of a ceramic ring for pad printing can vary depending on several factors, including the frequency of use, printing conditions, maintenance practices, and the specific ceramic material used. With proper care and maintenance, ceramic rings can offer a long lifespan, providing reliable performance for an extended period. Regular inspections and replacement of worn-out rings are recommended to ensure optimal printing results.

Two Color Pad Printer With Shutter For Bottle Cap

Two Color Pad Printer With shuttle for Coffee Machine

One Color Pad Printer for Garments, Tagless Logo

E-MALL: lina@engyprint.cn

ADD: No.25 Building, No.2 Longyan Rd., Longyan Industrial Park,Dongguan , Guangdong , China.

Copyright © Engyprint Tech Company Ltd. Technical Support: Molan Network

We will contact you within 1 working day, please pay attention to the mail with the suffix “lina@engyprint.cn ”.