I.Introduction

If you’re delving into the world of industrial printing, you’ve likely encountered a bewildering array of terms. Two of the most common are “photopolymer plates” and “clichés.” They’re often discussed in similar contexts, leading to a common and critical question: are they the same thing?

The short and definitive answer is no. While both are types of printing plates used to transfer an image, their composition, structure, and the printing technology they are designed for are fundamentally different. Confusing the two can lead to significant issues in your printing workflow, from poor quality to wasted material to even damage to your equipment. This single misconception can be the difference between a successful, high-quality production run and a frustrating, costly failure.

This article will serve as your essential guide to understanding the distinct roles of clichés and photopolymer plates. We will demystify these two types of plates, helping pad printing machine users understand why a cliché is essential for their process and when a photopolymer plate might be used instead. By the end of this deep dive, you’ll have the professional knowledge to make informed decisions for your printing operations.

II. Understanding the Cliche Plate

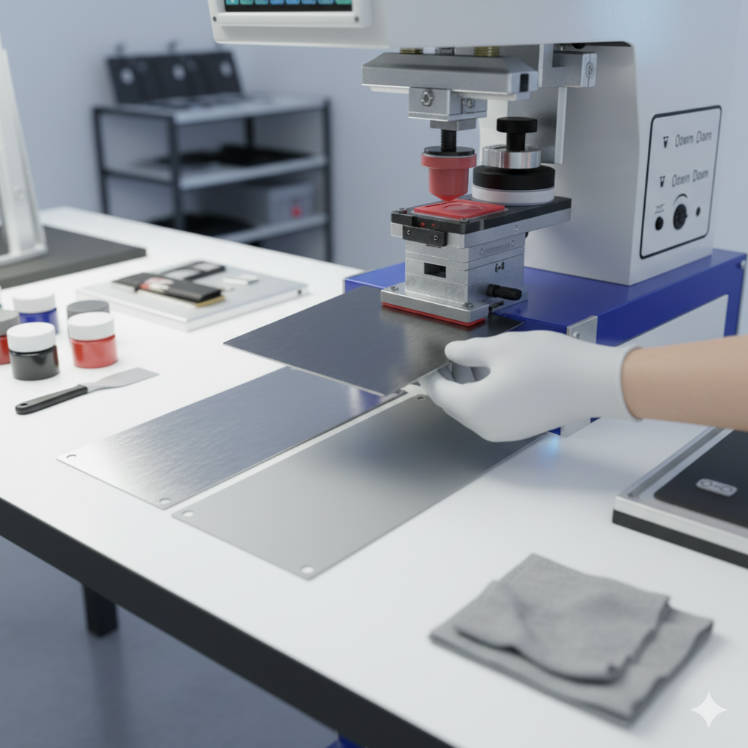

For anyone operating a pad printing machine, the heart of the system is the cliché plate. Unlike a stamp, which has a raised surface, a cliché is an intaglio printing plate, meaning it is specifically designed with a recessed or etched image. This fundamental difference is what allows for the precise, high-quality printing that pad printing is known for. The cliché is the foundation of the process, holding the intricate details of your design and preparing them for transfer.

The process is a finely tuned dance of ink and precision, a masterpiece of engineering. First, the cliché plate is flooded with ink by an ink cup or an open inkwell system. A precision-engineered doctor blade then glides over the surface, scraping away all excess ink and leaving a perfectly level, controlled layer of ink only within the microscopic wells of the etched image area. The pad printer’s silicone pad then presses firmly onto this plate, physically lifting the ink from the etched image. The unique properties of the silicone pad allow it to pick up the ink perfectly and then transfer it cleanly onto a three-dimensional object, conforming to its contours without distortion.

This ability to hold ink within a recessed area is the key function of a cliché, making it the only plate type suitable for a pad printing system. Without the intaglio design, the pad would have no controlled ink source to pick up from, and the doctor blade would be useless. This makes selecting the right cliche plate a critical first step in any pad printing project.

Cliché plates are manufactured from a variety of materials, each suited for different production needs and budgets.

- Hardened Steel Plates: These are the workhorses of the industry, offering exceptional durability and lifespan. For high-volume production runs (often over 1 million impressions) or projects requiring the sharpest, most intricate detail, a hardened steel cliché is the undisputed champion. The etching on these plates is a permanent part of the material, offering unmatched repeatability.

- Thin Steel Plates: A more cost-effective version of hardened steel, these are still very durable (hundreds of thousands of impressions) and are often used in systems that require a lower profile plate. They offer a great balance of longevity and cost.

- Polymer Plates: Also known as photopolymer or nylon plates, these are a different type from the kind used in stamp making. They are typically used for shorter runs (10,000 to 50,000 impressions) or for quick prototypes because they are less expensive and can be produced in-house with basic UV exposure equipment. While they are a great entry point, they are not as durable as their steel counterparts and are prone to wear on longer runs.

- Ceramic Plates: These are the premium option, highly resistant to wear and known for their ability to hold very fine lines and detail. They are ideal for high-end graphics and extremely long-life applications in specific industrial settings.

We work with many reputable Pad Printing Cliche Plates manufacturers to ensure we provide the best product for our clients. Whether you need aluminum printing plates for a specific application or are looking for a reliable Cliche Plates wholesale partner, understanding the material and its purpose is critical to success. The durability and precision of these plates are what enable pad printing to reproduce logos, text, and graphics with flawless consistency on an immense variety of products, from medical devices to promotional items.

III. Understanding the Photopolymer Plate

Now that we have a solid grasp of the cliché’s role, let’s turn our attention to the photopolymer plate. This is where a great deal of confusion arises, as the term “photopolymer” is used for both types of plates. However, their physical properties and intended use are worlds apart, and mistaking one for the other will lead to immediate and critical failure in your printing process.

A photopolymer plate, in the context of its primary application, is a flexible, raised-relief printing plate. This means that after a chemical process, the image area stands out in relief, literally raised above the non-image area. The process of creating this plate involves exposing a light-sensitive polymer to UV light through a negative film. The areas exposed to light harden, while the unexposed areas remain soft and are then washed away with water or a specific solution. The end result is a flexible sheet with a raised, reverse image.

The primary use for this type of plate is in flexography and for making traditional rubber stamps. In these processes, the raised image is inked by a roller and then pressed directly onto a flat substrate, such as paper, cardboard, or plastic film. This method is highly effective for printing large areas, simple text, or bold graphics on flat, often flexible, surfaces like product labels or packaging. It’s a direct, one-step transfer process from a raised surface.

For a user of a pad printing machine, a photopolymer plate is not a viable alternative to a cliché. The raised-relief structure of the plate directly conflicts with the core mechanics of a pad printer. The doctor blade, which is designed to scrape ink from a flat surface, would be unable to properly clean the plate. It would simply ride over the raised image area, leaving a layer of ink everywhere. This would lead to ink being spread all over the plate, resulting in a completely smudged, illegible print. The recessed-image cliché and the doctor blade are a matched pair, working in tandem to deliver the precision that pad printing requires. Attempting to substitute one for the other will simply not work and could potentially damage your doctor blade and ink cup system.

IV. Key Differences and a Comparison Chart

To put it all into perspective, let’s look at a side-by-side comparison of the two plate types. This table highlights why a cliché plate is indispensable for pad printing while a photopolymer plate is ideal for different applications.

| Feature | Cliche Plate | Photopolymer Plate |

| Primary Printing Method | Pad Printing (Intaglio) | Flexography / Stamp Making (Raised-Relief) |

| Plate Surface | Recessed, etched image | Raised, relief image |

| Material | Hardened Steel, Thin Steel, Polymer, Ceramic | Light-sensitive photopolymer |

| Key Function | Holds ink within the recessed image, allowing for clean scraping by a doctor blade | Transfers ink from the raised image directly to the substrate |

| Ideal Use Case | High-precision printing on 3D objects with fine detail and complex shapes | High-speed, large-area printing on flat, flexible surfaces like labels or simple stamps |

| Typical Durability | Thousands to millions of impressions (Steel) | Thousands of impressions |

| Required Equipment | Pad printer with a doctor blade/ink cup | Flexo press or stamp-making machine |

In essence, the entire operational principle of a pad printer is built around the use of a recessed cliché plate and a doctor blade. They are a single, integrated system. Attempting to use a raised-relief photopolymer plate would be like trying to pour water into a sieve—it just won’t work. For anyone looking for a reputable Cliche Plates supplier or considering Pad Printing Cliche Plates wholesale, understanding this distinction is the first and most crucial step toward a successful printing operation.

V. Conclusion: Why This Matters to You

We’ve established the critical difference between these two plate types. For users of a pad printing machine, the takeaway is clear: you must use a cliché plate. This specialized, recessed plate is the only technology that will work with your machine to deliver the crisp, clean, and consistent prints you need to succeed. Using a photopolymer plate in a pad printer is not just inefficient; it’s physically incompatible with the machine’s design.

Choosing the right plate is not just a technical detail; it’s a fundamental decision that directly impacts the quality of your product and the efficiency of your workflow. Whether you’re a new user setting up your first machine or a seasoned professional sourcing from a new Cliche Plates factory, remember to verify that you are getting the correct tool for the job.

By using the right plates, you ensure your pad printing machine can live up to its full potential, allowing you to reproduce intricate details on a wide range of surfaces with unparalleled precision and reliability, time after time.