I. Introduction: Navigating the Complexities of Industrial Product Decoration

In the fast-paced world of manufacturing and product decoration, the method you choose for applying logos, graphics, and text can be a critical factor in a project’s success. The decision goes far beyond a simple aesthetic choice; it impacts production efficiency, cost-effectiveness, and the final product’s quality and durability. For engineers, production managers, and business owners, the sheer volume of available technologies can be overwhelming. While screen printing, laser marking, and digital printing each have their place, two methods stand out for their specific applications in high-volume industrial settings: pad printing and dry offset printing. Both are workhorses of the industry, but they operate on fundamentally different principles and excel in distinct scenarios. Understanding these differences is not just about technical knowledge; it is about making a strategic business decision that will optimize your workflow and ROI for years to come.

This article is designed to be your comprehensive guide, a professional resource that cuts through the marketing jargon and provides a clear, data-driven comparison to help you confidently answer the question: which is best for your project?

We will delve deep into the mechanics of each technology, exploring their respective strengths, ideal applications, and operational considerations. Our goal is to empower you with the knowledge to make an informed choice, whether you are in the market for a new pad printing machine, a dry offset system, or are simply evaluating which process is right for an upcoming production run. For many, the search begins with a simple query, such as “what is the best pad printer for sale?” or “how much does an automatic pad printing machine price?”, but the answer lies in a much broader analysis. This article aims to provide that comprehensive context, moving beyond surface-level specifications to reveal the true operational advantages of each printing method.

The core of this decision often comes down to three key variables: the geometry of your product, the required production volume, and your budget. For a manufacturer dealing with thousands of small, irregularly shaped components, the flexibility of pad printing is often the most logical choice. Conversely, a company producing millions of cylindrical beverage caps would find the speed and efficiency of dry offset to be non-negotiable. This guide serves as an essential resource for anyone tasked with purchasing new pad printing equipment or optimizing an existing production line. The stakes are high in industrial printing, and the right choice can lead to significant savings and a superior finished product.

II. Understanding Pad Printing: Strengths and Applications

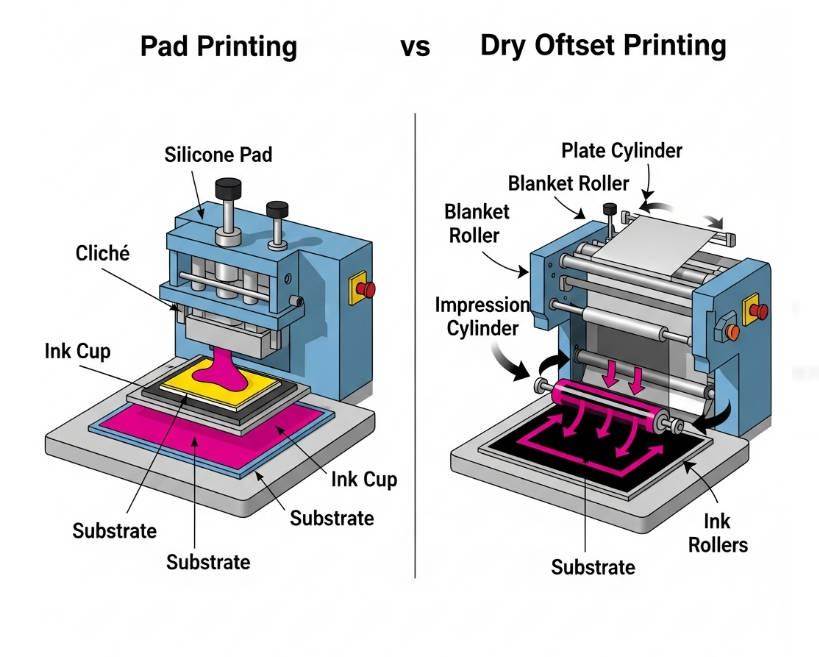

Pad printing, also known as tampography printing machine, is a highly versatile and specialized process that has become indispensable in a wide range of industries, from medical manufacturing to promotional products. At its core, the process involves transferring a 2-D image from an engraved plate (cliché) via a silicone pad onto a 3-D object. This seemingly simple mechanism allows for a level of flexibility and precision that is unmatched by other methods. The key component is the silicone pad itself, which can be molded into various shapes and sizes, enabling it to conform perfectly to a product’s contours, whether they are convex, concave, cylindrical, or irregularly shaped. This unique ability to print on non-flat surfaces is the cornerstone of its application and success.

The greatest strength of a pad printing machine is its unparalleled ability to print on virtually any three-dimensional object, regardless of its shape or material. This makes it the ideal solution for products that are impossible to decorate with other methods. Think of the numbers on a calculator key, the logo on a golf ball, or the intricate markings on a medical instrument. These are all examples of complex geometries that a flat printing surface could never handle. The silicone pad acts as a highly adaptable medium, picking up the ink from the etched cliché and precisely depositing it onto the product, even into recessed areas or around tight curves. This flexibility extends to the substrates as well, with pad printing being successfully used on plastics, metals, glass, ceramics, and even fabrics.

When considering a pad printer for sale, one of the key factors to evaluate is its level of automation. Automatic pad printing machines are the go-to choice for high-volume, repetitive tasks where speed and consistency are paramount. These systems can integrate seamlessly into a production line, handling everything from part feeding and printing to curing and ejection. For smaller operations or specialized tasks, a semi-automatic pad printing machine offers a great balance of control and efficiency, with an operator manually loading and unloading parts. The most basic models, such as a desktop pad printing machine, are perfect for prototyping, small-batch runs, or companies with a lower initial pad printer cost. This tiered approach to automation allows businesses to scale their printing capabilities as their production needs grow.

Beyond single-color applications, many manufacturers require multi color pad printing capabilities. A 2 color pad printing machine or even a 4 color pad printing machine uses a carousel system to cycle through multiple plates and pads, allowing for the precise registration of different colors on a single product without the need for manual alignment. This is crucial for brands that rely on multi-colored logos and graphics to maintain their corporate identity. For example, a sports equipment company might use a tampography printing machine to print its two-color logo on thousands of golf balls or hockey pucks, a task that would be prohibitively slow and expensive with manual methods.

Another significant advantage of this technology is its efficiency in handling diverse product lines. Unlike other printing methods that require extensive setup and costly tooling for each new job, a pad printing setup can often be changed over in a matter of minutes. Swapping out a cliché plate and a silicone pad is a quick and straightforward process, making pad printing an extremely cost-effective choice for short to medium production runs where a variety of products need to be decorated. This flexibility is a key reason why an industrial pad printing machine is a staple in contract manufacturing and prototyping shops.

III. Understanding Dry Offset Printing: Strengths and Applications

Dry offset printing is a specialized form of rotary letterpress printing, distinguished by its use of a single, flexible rubber blanket to transfer multiple colors from different plates onto a substrate in one pass. Unlike traditional offset printing, it does not use a dampening solution (hence the “dry” in its name), making the process cleaner and more efficient. The technology is specifically designed for decorating rigid, pre-formed plastic objects that are typically cylindrical, conical, or slightly tapered. Its primary advantage is speed, and it is the undisputed champion for high-volume production of products like caps, lids, tubes, and drinking cups.

The process of dry offset printing is a marvel of industrial engineering, with machines capable of decorating thousands of parts per hour. In a typical setup, a series of individual color stations each have a printing plate containing a single color’s image. These plates transfer their respective inks to an inking roller, which then applies the ink to a master blanket roller. As the product (e.g., a plastic cup) rotates, it comes into contact with the master blanket, and all colors are transferred simultaneously in a single, high-speed motion. This is in stark contrast to multi color pad printing, which requires a separate print cycle for each color. This single-pass, multi-color capability is the reason for dry offset’s incredible speed, making it the most economical choice for mass production.

A prime example of a leading dry offset machine is the Omso DM45, a name often associated with high-speed, high-quality industrial printing. The DM45 and similar models are engineered to operate continuously with minimal downtime, making them a cornerstone of production lines for the food and beverage, pharmaceutical, and cosmetic industries. The main benefit of a dry offset machine is its unparalleled efficiency and speed for long production runs of uniformly shaped products. For a project that requires millions of containers or closures to be decorated with a consistent logo, dry offset is the only practical solution. Its initial investment and setup costs are significantly higher than that of a cheap pad printer, but this is quickly offset by its low cost-per-part in mass production scenarios.

While dry offset excels in speed and consistency, it lacks the versatility of pad printing. Its rigid blanket is not designed to conform to complex, irregular shapes. It is purpose-built for its domain: printing on uniform, symmetrical surfaces. Attempting to use a dry offset machine to print on an uneven surface would result in a partial or distorted image. This limitation is what defines its niche and separates it so clearly from the applications where a pad printer for tagless logo on a garment or a logo on a medical device would be necessary. The quality of a dry offset print is also exceptional, offering sharp, clean lines and vibrant colors that are durable and resistant to fading, which is crucial for consumer products that undergo a great deal of handling.

IV. Direct Comparison: Pad Printing vs. Dry Offset

Now that we have a solid understanding of each technology’s core principles and strengths, it is time to put them side-by-side. While both pad printing and dry offset are used for product decoration, their suitability for a given project is determined by a few critical factors. The following comparison table provides a high-level overview of their key differences, serving as a quick reference guide for your decision-making process.

| Feature | Pad Printing | Dry Offset Printing |

| Ideal Product Geometry | Irregular, 3D, Curved, Recessed, Flat | Cylindrical, Conical, Symmetrical Surfaces |

| Production Speed | Low to Medium (e.g., 500-1,500 parts/hr) | Very High (e.g., 20,000+ parts/hr) |

| Setup & Changeover Time | Quick and Flexible | Longer and More Complex |

| Print Resolution | Excellent for Fine Details and Small Text | Excellent for Crisp, Seamless Wrap-Around Images |

| Ideal Run Volume | Small to Medium | High to Mass Production |

| Initial Equipment Cost | Generally lower for a single-color or 2 color pad printing machine. | Generally higher for a high-speed automatic machine. |

The Decisive Factor: Surface Geometry

The most significant difference between the two is their approach to surface geometry. Pad printing equipment is designed for ultimate flexibility, making it the only viable option for printing on products with complex, non-uniform surfaces. The deformable silicone pad is the core of this capability, as it can conform to concave and convex shapes, print into small depressions, and wrap around sharp corners. If your product is a medical device with an intricate logo on a curved casing or a promotional stress ball with a brand name on its spherical shape, a pad printing machine is the only logical choice.

Conversely, dry offset printing is a specialized technology built for speed on symmetrical objects. The rigid blanket requires a consistent, uninterrupted surface to roll the image onto. It cannot handle an irregular shape, a protruding feature, or a recessed area. This means that dry offset is purpose-built for its niche of cylindrical and conical objects and is completely unsuitable for any other product geometry.

Speed vs. Versatility: A Matter of Scale

Production volume is the second major factor. Dry offset printing is the uncontested king of high-speed, high-volume production. A single dry offset machine can outperform an entire line of pad printers when the job involves millions of identical parts. This efficiency is why you see dry offset used for items like yogurt cups, plastic lids, and bottle caps. For businesses that need to decorate tens of thousands of parts per hour, the investment in a high-speed dry offset system is a necessity.

However, this speed comes at the expense of flexibility. For projects with lower volumes, frequent design changes, or a diverse range of products, the lengthy setup and initial cost of a dry offset machine are impractical. A pad printing machine excels in these scenarios. A single industrial pad printing machine can be used to print a variety of different products simply by swapping out the clichés and pads. This makes it a far more versatile and cost-effective option for businesses that need to handle short-to-medium runs of diverse products, without the high barrier to entry of a dry offset machine. For those searching for a pad printing supplier, this versatility is often a key selling point.

V. Practical Scenarios: A Decision-Making Framework

To solidify your understanding and help you apply the technical information to real-world business decisions, let’s walk through three distinct scenarios. Each one highlights the key factors that lead to choosing either pad printing or dry offset as the superior solution.

Scenario A: The Medical Device Manufacturer

You are a manufacturer of a new line of electronic medical devices. The product features a curved plastic casing and requires a high-resolution logo and serial number to be printed on the back. The logo is multi-color, and the product’s surface has a slight texture and a complex contour that makes it impossible to use flat printing methods. You anticipate a production volume of around 50,000 units per year. You need a reliable, precise, and repeatable process.

- Analysis: The most critical factor here is the product’s geometry. The curved and textured surface immediately rules out dry offset printing, which requires a uniform, cylindrical shape. The need for precision and multi-color registration on an irregular surface points directly to pad printing.

- Conclusion: A multi color pad printing system is the ideal choice for this project. The upfront pad printer price will be a manageable investment, and the machine’s ability to precisely print on a complex surface ensures product quality. The anticipated volume is a perfect fit for a semi-automatic or automatic pad printing machine, which can handle the production volume efficiently without the prohibitive cost of a dry offset system.

Scenario B: The Beverage Bottle Cap Producer

Your company has secured a major contract to produce plastic caps for a new energy drink. The contract requires you to decorate 2 million caps per week with a two-color logo. The caps are perfectly cylindrical. Speed and consistency are paramount, as even a small amount of downtime could lead to significant financial penalties. The production line must run 24/7 to meet the demand.

- Analysis: This scenario is defined by its sheer scale and the uniformity of the product. The cylindrical shape and extremely high volume requirements make this a textbook case for dry offset printing. Pad printing, even with multiple machines, simply cannot compete with the speed of a single, high-performance dry offset machine.

- Conclusion: A dry offset printing system, such as a high-speed Omso DM45, is the only viable solution. While the initial investment is high, the low cost-per-unit in mass production makes it the most economical choice. The ability to decorate tens of thousands of parts per hour is a non-negotiable requirement that only dry offset can fulfill, guaranteeing that production targets are met efficiently.

Scenario C: The Start-Up with a New Product Line

You’ve launched a new brand of promotional pens and need to print your company logo on them. The pens have a sleek, cylindrical body, but you plan to offer several different pen models, colors, and designs throughout the year. You have a limited initial budget and need a system that can handle small runs for a variety of orders.

- Analysis: While the product (a pen) is cylindrical and could technically be handled by a dry offset machine, the key constraints are the limited budget and the need for flexibility across different product lines and smaller order quantities. The high initial cost and complex setup of a dry offset system make it a poor fit for this scenario.

- Conclusion: A 2 color pad printing machine is the perfect starting point. Its lower initial pad printer cost makes it a smart investment for a start-up. The quick changeover time for new designs and different products allows for maximum flexibility. As the business grows and specific models gain popularity, you can scale up with more advanced industrial pad printing machines or even consider a dry offset machine for a single, high-volume product line in the future.

VI. Conclusion: Making Your Final Decision

The debate between pad printing and dry offset is not a matter of which technology is inherently “better,” but rather which is the superior fit for your specific operational needs. Both are powerful tools in the industrial printing landscape, each with a distinct purpose and set of capabilities. Pad printing is the master of versatility, offering unmatched precision and flexibility for printing on a wide array of irregular shapes and substrates. It is the go-to solution for intricate, low-to-medium volume projects where a tampography printing machine provides a cost-effective and adaptable solution.

Dry offset, on the other hand, is built for scale. It is a high-speed workhorse designed to handle mass production with a consistency and efficiency that is unparalleled. For millions of identical, cylindrical products, the investment in a dry offset system pays for itself many times over in speed and a low cost-per-part. Ultimately, the choice comes down to a simple formula: prioritize versatility and precision for complex shapes with pad printing, or prioritize speed and efficiency for high-volume cylindrical products with dry offset.

Before you make your final decision, take a moment to evaluate your project against these key criteria:

- Product Geometry: Is your product flat, curved, textured, or irregular?

- Production Volume: Are you producing hundreds of thousands or millions of parts per month?

- Budget: Do you need a flexible entry-level machine or a high-volume, long-term solution?

By honestly assessing these factors, you can confidently select the printing method that will not only meet your production demands but also provide the best long-term return on your investment. Whether you are looking for a pad printing machine to handle diverse products or a dry offset system for a single high-volume run, understanding these fundamental differences is the first and most crucial step toward a successful printing operation.