Thin steel pad printing plates, or clichés, have emerged as a dominant force in the industry, offering a powerful combination of low initial costs, exceptional image reproduction, and streamlined operational efficiency. For businesses navigating the demands of short-to-medium production runs, these plates represent the ultimate sweet spot, delivering high-quality, detailed prints without the significant investment and longer lead times associated with traditional thick steel plates. This unique balance makes them the most cost-effective and versatile solution for a vast range of applications, from promotional products to intricate medical and electronic components.

The Sweet Spot of Pad Printing: Unlocking Cost-Effectiveness and Superior Quality with Thin Steel Plates

In the world of pad printing, the choice of printing plate—or cliché—is a foundational decision that directly impacts everything from budget and turnaround time to the final quality of the printed image. For decades, the choice was a simple trade-off between inexpensive but short-lived photopolymer plates and durable but costly thick steel plates. Today, however, thin steel plates have redefined this landscape. By harnessing modern laser etching technology, they provide a solution that marries economic viability with high-fidelity printing, making them a strategic asset for any modern printing operation.

This article delves into the distinct advantages of thin steel pad printing plates, exploring how they achieve an ideal equilibrium between cost-effectiveness and quality. We will analyze their financial benefits, their capacity for producing sharp and consistent prints, and the operational efficiencies they bring to the production floor.

Table of Contents

- What Exactly Are Thin Steel Pad Printing Plates?

- The Core Advantage: Why Thin Steel Plates Excel in Cost-Effectiveness

- Achieving Uncompromised Print Quality with Thin Plates

- Practical and Operational Benefits: Streamlining Your Workflow

- When is a Thin Steel Plate the Right Choice for Your Project?

- Conclusion: The Strategic Choice for Modern Pad Printing

What Exactly Are Thin Steel Pad Printing Plates?

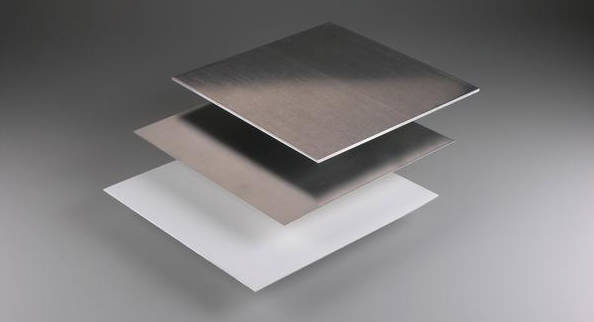

Before exploring their benefits, it’s essential to understand what thin steel plates are and how they differ from their counterparts. A pad printing plate, or cliché, is a flat plate that holds the desired artwork etched into its surface. This etched area holds ink, which is then picked up by a silicone pad and transferred to the product.

Thin steel plates are typically made from high-quality spring steel and have a thickness ranging from 0.25mm to 0.5mm. They are hardened and precision-ground to ensure a perfectly flat and smooth surface, which is critical for clean doctoring by an ink cup or doctor blade. Their popularity has surged with the rise of C02 and fiber laser etching systems, which can quickly and precisely engrave intricate images onto their surface.

To put their role in context, let’s compare the three primary types of pad printing plates:

| Plate Type | Material | Typical Lifespan (Impressions) | Key Characteristics |

|---|---|---|---|

| Thin Steel Plates | Hardened Spring Steel | 50,000 – 100,000+ | Excellent balance of cost, quality, and durability. Ideal for laser etching. |

| Thick Steel Plates | Tool Steel (approx. 10mm thick) | 1,000,000+ | Highest durability for extremely long runs; high initial cost and long processing time. |

| Photopolymer Plates | Light-Sensitive Plastic | 5,000 – 20,000 | Lowest cost and fastest to make in-house for short runs; lower resolution and durability. |

The Core Advantage: Why Thin Steel Plates Excel in Cost-Effectiveness

The primary driver for the adoption of thin steel plates is their remarkable cost-effectiveness. This isn’t just about a lower price tag; it’s about a holistic financial benefit that touches multiple aspects of the production process. What makes them so economically advantageous?

Lower Initial Investment and Processing Costs

The most immediate financial benefit is the lower upfront cost. Compared to a 10mm thick steel cliché, a 0.5mm thin steel plate uses significantly less raw material, making it inherently cheaper to procure. This cost advantage is amplified during the etching process.

Thick steel plates often require complex, multi-step chemical etching processes involving hazardous acids, which are time-consuming and require specialized handling and disposal. In contrast, thin steel plates are perfectly suited for direct-to-plate laser etching. This computer-controlled process is not only faster but also eliminates the costs associated with films, chemicals, and extensive labor, driving down the total cost of a finished, press-ready plate.

Optimizing Cost-Per-Impression for Modern Production Runs

While a thick steel plate offers an unbeatable **cost-per-impression** over a run of several million prints, this scenario is becoming less common. Modern manufacturing is characterized by product diversification, customization, and just-in-time inventory, leading to more frequent, shorter production runs.

This is where thin steel plates shine. With a robust lifespan of up to 100,000 impressions or more, they comfortably handle the vast majority of short-to-medium-sized jobs. For these runs, the high initial cost of a thick steel plate can never be fully amortized, making it an economically inefficient choice. A thin steel plate, however, provides the perfect durability for the job at a fraction of the cost, resulting in a far superior return on investment for most typical projects.

Reduced Operational and Storage Costs

The financial benefits extend to the shop floor. Thin steel plates are lightweight and flexible, making them easier and safer for operators to handle, install, and store. A box of 100 thin plates takes up a fraction of the space and weight of 100 thick plates. This reduces the need for bulky storage systems and minimizes the risk of operator strain or injury. The faster setup times associated with these lighter plates also translate directly into reduced machine downtime and increased labor productivity.

Achieving Uncompromised Print Quality with Thin Plates

Cost-effectiveness would be meaningless without quality. Fortunately, thin steel plates excel in this area, often outperforming photopolymer plates and rivaling the quality of even the most expensive thick steel plates, especially when paired with modern etching technology.

The Precision of Modern Laser Etching Technologies

The true game-changer for thin steel clichés is the advent of fiber laser etchers. Unlike older CO2 lasers or chemical etching, fiber lasers produce an extremely fine and focused beam that can engrave incredibly precise and detailed artwork. This technology allows for:

- Sharp, Well-Defined Edges: Lasers create clean, vertical walls in the etched cells, preventing ink from bleeding and ensuring crisp lines and text.

- Consistent Etch Depth: Computer control ensures a uniform etch depth across the entire image, which is critical for consistent ink deposit and color opacity.

- Fine Halftones and Screens: The precision of the laser enables the reliable reproduction of very fine halftone dots (up to 200 LPI or more), allowing for photorealistic images and smooth gradients.

This level of precision was once the exclusive domain of expertly crafted thick steel plates but is now easily and affordably achievable with thin steel.

Superior Ink Transfer and Image Fidelity

The quality of an etch directly impacts ink transfer. The smooth, hardened surface of a thin steel plate allows the ink cup’s ceramic ring or the steel doctor blade to shear the excess ink cleanly from the surface, leaving a precise volume of ink only in the etched artwork. This clean doctoring is essential for high-fidelity printing.

The perfectly formed ink wells created by laser etching pick up and release ink predictably onto the silicone pad. This results in an exact replication of the artwork on the substrate, free from smudges, pinholes, or “saw-toothing” on the edges that can plague lower-quality plates. The result is a vibrant, sharp, and professional print, every time.

Consistency Across the Production Run

Durability is a component of quality. While photopolymer plates can wear down quickly, causing the print quality to degrade over a run, thin steel plates maintain their integrity. The hardened steel surface is highly resistant to the abrasive action of the doctor blade or ink cup. This ensures that the 50,000th impression looks just as sharp and clean as the first, a critical requirement for maintaining brand standards and product quality.

Practical and Operational Benefits: Streamlining Your Workflow

Beyond cost and quality, thin steel plates introduce significant operational efficiencies that help streamline the entire pad printing workflow.

Faster Turnaround and Plate Production

In a fast-paced market, speed is a competitive advantage. The process of creating a thin steel cliché with a laser is exceptionally fast. An operator can take a digital art file and produce a press-ready plate in a matter of minutes. There is no need for film positives, UV exposure units, washout processes, or long drying times associated with photopolymer plates. This rapid turnaround allows businesses to respond quickly to customer demands and tight deadlines.

Enhanced Safety and Environmental Friendliness

The traditional method of etching thick steel plates involves ferric chloride and other corrosive acids, which pose significant health and safety risks to employees and create hazardous waste that is costly to dispose of. Laser etching thin steel plates is a clean, chemical-free process. It produces no hazardous byproducts, requires no special ventilation (beyond a fume extractor), and is inherently safer for operators. This aligns with modern corporate responsibility goals and reduces regulatory compliance burdens.

Ease of Handling and Machine Setup

The physical nature of thin steel plates simplifies work on the production floor. Their light weight and flexibility make them easy to mount onto the magnetic or mechanical plate bases used in pad printing machines. This reduces setup and changeover times between jobs, maximizing machine uptime and overall throughput. Operators can switch from one job to another more quickly, boosting the overall efficiency of the printing department.

When is a Thin Steel Plate the Right Choice for Your Project?

Thin steel plates are a versatile and powerful option, but are they always the best choice? Here are key questions to ask when deciding if a thin steel cliché is right for your application:

- What is your expected production run size? If your run is between 1,000 and 100,000 impressions, a thin steel plate is almost certainly the most cost-effective choice.

- How critical is fine detail and high resolution? For jobs requiring fine text, intricate logos, or halftone images, the laser-etched precision of a thin steel plate is a major advantage over photopolymer.

- How quickly do you need the plates? If you need rapid turnaround from artwork to production, the speed of laser-etching thin steel plates is unmatched.

- What is your budget for plates? Thin steel plates offer a significantly lower initial cost than thick steel, making them ideal for projects with tighter budget constraints.

- Are environmental and safety concerns a priority? The chemical-free laser etching process makes thin steel the more responsible choice.

A thin steel plate is the ideal choice for a majority of modern pad printing jobs, including promotional products, medical device marking, automotive components, electronic housings, and apparel tagging.

Conclusion: The Strategic Choice for Modern Pad Printing

Thin steel pad printing plates have fundamentally shifted the economic and quality calculus of the industry. They are no longer a “middle-of-the-road” option but have become the strategic choice for businesses aiming to maximize efficiency, quality, and profitability. By delivering the high-resolution imaging of premium plates at a fraction of the cost, they resolve the age-old conflict between budget and quality.

Their synergy with fast, precise, and clean laser-etching technology has created a workflow that is faster, safer, and more cost-effective than ever before. For any company looking to stay competitive in the demanding world of pad printing, embracing the advantages of thin steel plates is not just an option—it’s an essential step toward a more productive and profitable future.

pad printing plates, thin steel plates, pad printing clichés, cost-effective pad printing, pad printing quality, laser etched plates, thick vs thin steel plates, cost-per-impression, photopolymer plates, pad printing advantages, what is a pad printing cliché, pad printing etching, image fidelity, modern pad printing, pad printing workflow, plate durability, short-run pad printing