CUSTOMIZED PROCESS FOR A PAD MOLD

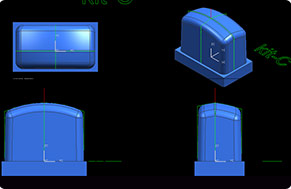

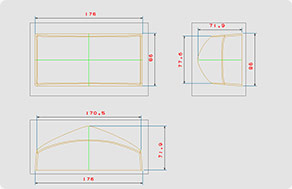

Step 1 : We will copy the pad dimension/shape and create the related 3D drawing accordingly

Step 2 : We prepare the 3D drawing(.stp) and send to client for confirmation

Step 1

Client needs to send the mold or pad 3D drawing (.stp) file to us for evaluation.

Step 2

Engyprint designs the pad printer according to the requirement.

Step 3

Prepare the quotation and discuss price with client.

Step 4

Confirm order and start production according to the approved 3D drawing.

Step 5

Check the pad mold quality carefully and pack them well for delivery.

Customized Process for Pad Printer

Step 1

Customer provides the basic requirement and start discussion with ENGY.

Step 2

Engyprint designs the pad printer according to the requirement.

Step 3

Engyprint provides the quotation after customer approved the machine solution.

Step 4

Client issues PO to Engprint and send the sample to us.

Step 5

Machine ready, Engyprint makes printing trial with sample and provides the related video to client for confirmation.

Step 6

Adjust the pad printer settings ready for printing and take the operation video to guide client use the printer .

Step 7

Customer approval, pack the machine for delivery.

Operation Instruction

FAQ

As we all know pad printer and silk screen printer are able to print various material, here are some tips to choose a suitable printer for your product :

Generally speaking:

1.Pad printer is for smaller size logo , silk screen printer is better for larger size logo

2.Pad printer can be used for irregular items printing( like different shape of toys, tools, home appliance, medical suppliers etc), silk screen printer is normally used for plane or curved surface only(like ball, syringe, paper, etc).

3.Pad printer need to match with fast dry ink, silk screen printer need to match with slow dry ink In order to find the best machine solution, we suggest to provide the below basic information for future discussion:

1.Product dimension and material

2.Logo dimension and how many colors are required 3.The logo location of the product ( in the central or at the side)

4.Production capacity requirement

5.Any other special demand.

Please don’t worry, Engyprint will follow the standard flow chart to train our customers to use the pad printer and silk screen printer.

1.We will adjust the machine to get it ready for printing before delivery from factory

2.Machine manual will be delivered together with the printer.

3.Operation video will be provided to client so that they can learn it step by step

4.Our experienced technician can carry out training courses if the customer can come to our factory

5.If any questions happen during the use of the printer, our after-sale service team( including sales person and technician) can provide in time service by video call or skype conference etc.

Of course, welcome to send drawings and products to us for sample testing.

If the sample testing done before the machine order, few amount will be charged for fixture and plate making, If the sample testing done after the machine order issued, sample test can be free of charge.

As we have our own consumables production line, there is no MOQ requirement for the consumables like thick/thin plate, ceramic ring, carbide ring, pad, pad mold, ink cup etc, for more detail information, please contact our professional sales team.

By the way, to provide one stop pad printer consumables solution is one of our best advantages.

There are two major ways of making the plate for pad printer on the market, by chemical etching or by laser engraving.

For both plate making methods, we can provide the related machines (like etching machine, fiber laser machine) and the related technologies, for fiber laser machine, if client can provide the ai drawing with vector diagram, Engyprint can provide the engraving service on the aluminum plate for testing.

download

10+years experienced engineers in factory

We design machine according to the real demandWe care about yoursatisfaction